Tire oil to diesel refining machine

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

As we know we can get tire oil from waste tire by pyrolysis plant, but, it seems lots of people want to get high quality diesel oil. Then, the tire oil to diesel become a very hot and highly profitable green project, which is low cost, easy to collect the raw material and can convert waste tyre oil to diesel (oil recovery rate is about 80%-90%)

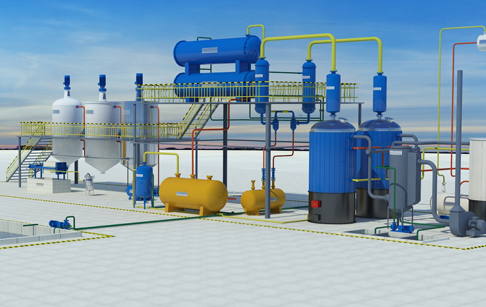

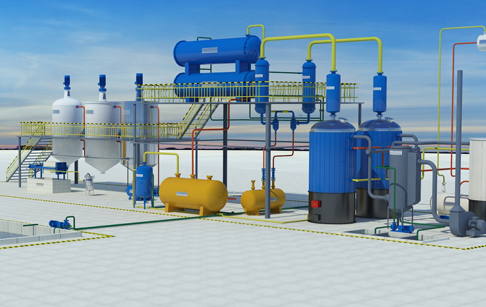

Tire oil to diesel refining machine

Why more and more people are willing to invest tire oil to diesel refining machine this new project? As we all known, with the car industry increasing, the number of waste tyres in the world increases sharply. At the same time, oil resources are decreasing every day. How to dispose of waste tyres and related problems?

Tire oil to diesel refining machine

Tire oil to diesel refining machine process tire oil to diesel

Firstly, the raw material enters the raw material precipitation tank through the oil pipe; then adds the degumming catalyst; after finishing this step, we can inject air into the precipitation tank for about 30 minutes through the air compressor; by this step, the degumming pyrolysis will be fully mixed with raw material. Next let the liquid subside for 3 hours.

Secondly, after 3 hours, the sediment of the raw material precipitation tank will be discharged, and then the crude oil, which has finished the precipitation, will be pulled into distillation tower through the oil pipe.

Thirdly, start to distill the oil with high temperature, and use fuel oil to heat distillation reactor; at this time, the raw material will be heated circularly between the oil heating furnace and distillation reactor; when it reaches the related temperature, the oil gas of each reactor will enter the heat exchange system and condenser system in order through the distillation tower. The final products including gasoline and diesel will be stored into oil tank respectively.

After processed by the pyrolysis oil distillation plant, the various kinds of waste oil can be turned into diesel or gasoline, which makes the pyrolysis oil price higher in the market and have wider applications. It is the best choice for the pyrolysis oil buyers to further process the oil.

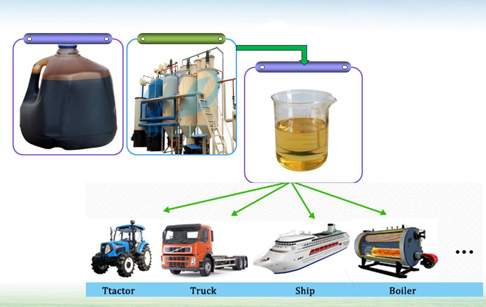

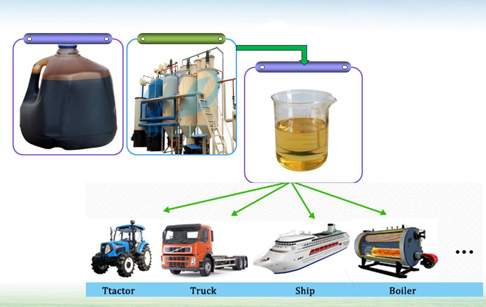

Tire oil to diesel refining machine can turn waste tyre oil to a high quality diesel. This machine not only applied to tyre oil also can use for plastic oil and waste engine oil. the final oil-diesel can be used for tractors, trucks, ships and generator power etc. If you want to buy distillation plant below information should be know:

Tire oil to diesel refining machine 3 D picture

• 100% waste tyre oil recovery is achieved (no churn left after the process)

• During and after the process; no soil, water or air pollution is observed.

• The most cost-effective waste tyre oil refining to diesel technology in the world.

• Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production.

• The process can be applied to plastic oil and waste engine oil.

• Vertical structure form, easy for cleaning and maintenance.

• The system creates an alternative source of energy to replace petroleum products and natural gas.

• System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent.

• System prevents the spread of diseases caused by waste tyres oil.

• We deliver plants with capacities of 5 ton to 50t/day and its multiples.

• The process of distillation has duration of 15 to 18 hours, depending on the quality of waste oil. Also it can work day and night. No need to stop.

Application of diesel oil ( refined by tire oil to diesel refining machine).

Diesel oil application

Tire oil to diesel refining machine

Why more and more people are willing to invest tire oil to diesel refining machine this new project? As we all known, with the car industry increasing, the number of waste tyres in the world increases sharply. At the same time, oil resources are decreasing every day. How to dispose of waste tyres and related problems?

Tire oil to diesel refining machine

Firstly, the raw material enters the raw material precipitation tank through the oil pipe; then adds the degumming catalyst; after finishing this step, we can inject air into the precipitation tank for about 30 minutes through the air compressor; by this step, the degumming pyrolysis will be fully mixed with raw material. Next let the liquid subside for 3 hours.

Secondly, after 3 hours, the sediment of the raw material precipitation tank will be discharged, and then the crude oil, which has finished the precipitation, will be pulled into distillation tower through the oil pipe.

Thirdly, start to distill the oil with high temperature, and use fuel oil to heat distillation reactor; at this time, the raw material will be heated circularly between the oil heating furnace and distillation reactor; when it reaches the related temperature, the oil gas of each reactor will enter the heat exchange system and condenser system in order through the distillation tower. The final products including gasoline and diesel will be stored into oil tank respectively.

After processed by the pyrolysis oil distillation plant, the various kinds of waste oil can be turned into diesel or gasoline, which makes the pyrolysis oil price higher in the market and have wider applications. It is the best choice for the pyrolysis oil buyers to further process the oil.

Tire oil to diesel refining machine can turn waste tyre oil to a high quality diesel. This machine not only applied to tyre oil also can use for plastic oil and waste engine oil. the final oil-diesel can be used for tractors, trucks, ships and generator power etc. If you want to buy distillation plant below information should be know:

Tire oil to diesel refining machine 3 D picture

• During and after the process; no soil, water or air pollution is observed.

• The most cost-effective waste tyre oil refining to diesel technology in the world.

• Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production.

• The process can be applied to plastic oil and waste engine oil.

• Vertical structure form, easy for cleaning and maintenance.

• The system creates an alternative source of energy to replace petroleum products and natural gas.

• System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent.

• System prevents the spread of diseases caused by waste tyres oil.

• We deliver plants with capacities of 5 ton to 50t/day and its multiples.

• The process of distillation has duration of 15 to 18 hours, depending on the quality of waste oil. Also it can work day and night. No need to stop.

Application of diesel oil ( refined by tire oil to diesel refining machine).

Diesel oil application

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications