Used engine oil recycling plant

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

Used engine oil recycling plant

Used engine oil recycling plant recycling engine oil to diesel

Used engine oil recycling plant

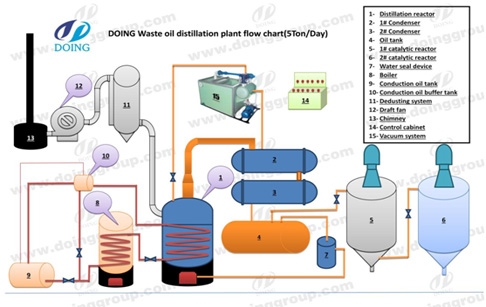

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The diesel will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system

Used engine oil recycling plant

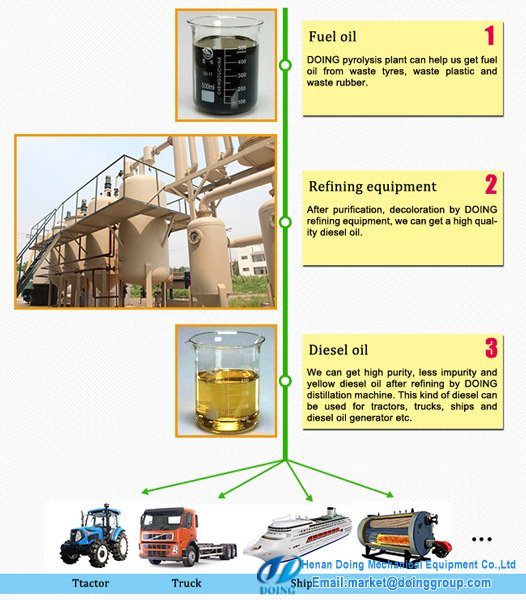

The main oil of the final oil is the diesel fuel oil.

You can add different additives in the final treated oil, you can get different oils.

And the machine can treat all kinds of the waste oil.

DOING Used engine oil recycling plant is very suitable for the oil refinery companies, also for the small oil company who want to make the oil by self.

Application of final oil- diesel

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications