Plastic recycling by pyrolysis micro plant

Waste plastic in our dailylife

DOING company plastic recycling by pyrolysis micro plant

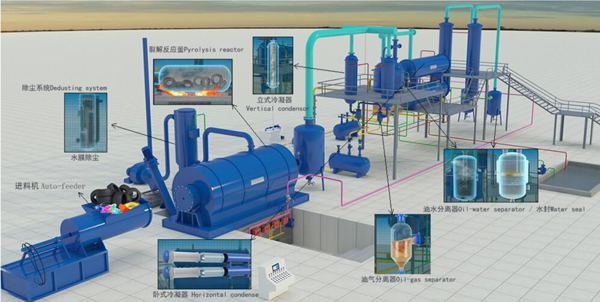

So what is the specific operation process of plastic recycling by pyrolysis micro plant?

Plastic recycling by pyrolysis micro plant

2. The reactor is heat treated, and the oil and gas are cracked at a temperature of 280 °C.

3. The fuel oil and gas enters the most important condensing system of the pyrolysis unit under the pressure of the reactor, and is liquefied into heavy oil and falls into the oil tank.

4.. For the carbon black produced in the combustion process, we now have the most advanced wind conveying carbon black discharge system in China. This system is more time-saving, labor-saving and reduces land occupy than previous carbon black discharge systems.

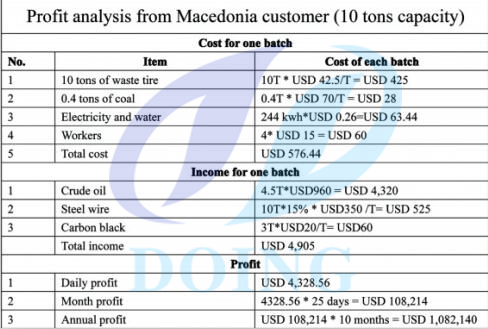

The most important thing is that the market value of the products we can get through this process is far from that of recycled plastics. As mentioned above, the scope of our use of plastic recycling by pyrolysis micro plant is not limited to just one raw material. It can handle not only waste plastics, but also waste tires. We have a Macedonian client who has cooperated with us for many years.

Macedinan customer visited our factory 3 times

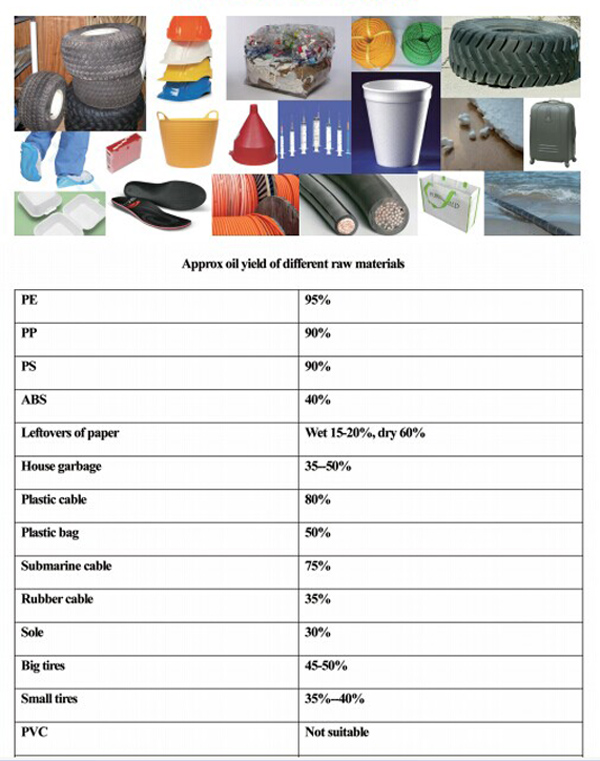

Since different waste plastics prices are different in the market, the benefits that can be obtained with different waste plastics are also different. Based on many years of the industry experience, we have summarized the oil yield of different waste plastics for your reference!

All kinds of waste plastic oil yield

What are the specific advantages of DOING company's plastic recycling by pyrolysis micro plant?

DOING plastic recycling by pyrolysis micro plant advantages

1. Adopt the most advanced and efficient condenser in the oil industry. In order to ensure the highest oil yield, a 3-stage condensing system is designed to ensure that the oil gas are sufficiently cooled to achieve the highest oil yield in the industry.

2. In addition to the oil rate, safety is also a major advantage of this equipment, to ensure that the reactor is not easy to crack with high safety guarantee, we also have supporting safety devices mainly including oil-water separator, water Seal, vacuum device.

3. Environmental protection is the outstanding advantage of our waste plastic pyrolysis plant. Regarding the cooling system, we mainly use circulating water cooling, there will be no waste water pollution; for the dust removal device, we use the water film dust removal system and dry pulse dust removal; Part of the exhaust gas will be recycled by the equipment, and the other part will be cleaned by the desulfurization and deodorization tower system.

Hope this article can break through people's views on the traditional treatment of waste plastics, and at the same time, let more people see new investment opportunities, because the traditional waste plastics incineration and landfill disposal methods are not only a threat to our living environment, but also a waste of resources. DOING company's plastic recycling by pyrolysis micro plant will open a new chapter in harmony between people and the environment, and will become a trend with unlimited market development potential!