New design of pyrolysis plant for conversion of waste tires into fuel

Waste tires

New design of pyrolysis plant for conversion of waste tires into fuel

The specific treatment process about new design of pyrolysis plant for conversion of waste tires into fuel is as follows:

Waste tire pyrolysis plant working process

1. The waste tire is sent to the reaction kettle through the automatic feeder device; or the waste steel wire in the waste tire is extracted by the wire drawing machine, and then the waste tire is processed into a 3-5 cmm tire piece by the tire crusher, and is sent into reator.

2. The reactor is heat treated, and after the temperature reaches 280 degrees, the oil and gas are cracked.

3. The oil and gas enters the condensing system and is liquefied into heavy oil and falls into the oil tank.

4. Deodorize and deodorize the heavy oil in the tank, and finally get fuel.

5. The carbon black produced during the combustion process is sucked up by the newly designed carbon black air transport system. Moreover, this system is more labor-saving, labor-saving and saves investment land area than the previous carbon black slagging system.

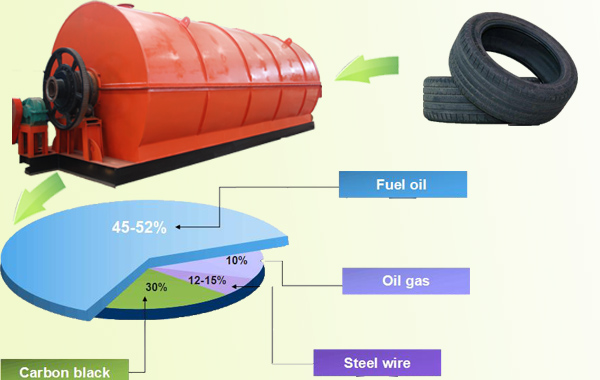

Waste tire pyrolysis plant final products

Carbon black application

As the new design of pyrolysis plant for conversion of waste tires into fuel, what is its new concrete manifestation? Mainly reflected in the following aspects:

A. Wind conveying carbon black discharge system

Carbon black discharge system updated

1. The traditional carbon black hoist needs to wait until the temperature of the reactor drops to about 100 degrees to start working. It takes 4-5 hours to wait for the temperature to drop. The latest wind conveying carbon black discharge system can start slagging at around 200 degrees, saving time.

2. The equipment is simple, only need one conveying pipe and one fan, saving floor space and reducing investment cost.

3. The carbon black emissions are relatively concentrated, which is convenient for post-packing and transportation.

4. Post-maintenance is simple.

5. The first manufacturer in China, quickly seize the market opportunity. The earlier the investment, the faster the income.

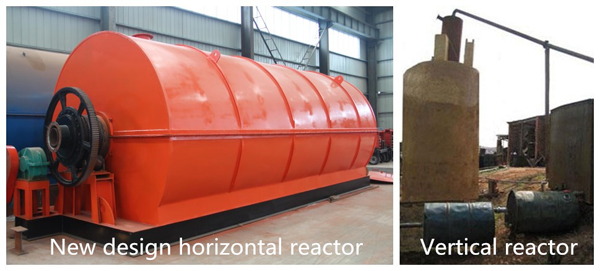

B. Horizontal reactor design update

New design horizontal reactor and vertical reactor compare

2. The vertical reactor has a slow cracking speed. Dongying's newly designed horizontal refinery reactor uses a 360-degree rotating structure, and the cracking speed of waste plastics is fast.

3. The vertical refiner is inconvenient to operate, the amount of labor is large, the material level is high, and the obtained product needs to use a crane. The horizontal reaction kettle can feed the raw materials into the reaction vessel through an automatic pushing device, and the operation is simple.

4. Since the vertical reactor is heated without the horizontal reactor being uniform, the oil and gas cracked are different. Therefore, the newly designed horizontal reactor can guarantee a higher oil yield.

C:About the treatment of exhaust gas

The tail gas generated by the traditional reactor is directly discharged into the air, which is extremely harmful to the environment. In the new design of pyrolysis plant for conversion of waste tires into fuel, part of the exhaust gas generated will be recycled by the equipment for the heating fuel used in the reactor; another part of the exhaust gas that cannot be recovered will be filtered by the desulfurization and deodorization tower system, and after filtration, the exhaust gas will be no-harmful to the human body. Substance. The filtered exhaust gas is re-discharged without any pollution to the air.

The latest waste tires pyrolysis plant is especially suitable for large-scale waste tire pyrolysis plants factory. At present, we have cooperated with domestic and foreign customers to have examples of the latest used old tires pyrolysis plant. The new design of pyrolysis plant for conversion of waste tires into fuel is characterized by a larger scale and a higher return on investment. A customer in Mexico previously purchased 10 sets of waste tires pyrolysis plant from us.Here is the photos the 10 sets pyrolysis plant installed in his country for your reference!

10 sets pyrolysis plant was installed in Moxico

Moxcio customer wind conveying carbon black discharge system