Home>FAQ>Waste Tyre Recycling Pyrolysis PlantWhy can we get fuel oil from waste tires by using pyrolysis way?

Home>FAQ>Waste Tyre Recycling Pyrolysis PlantWhy can we get fuel oil from waste tires by using pyrolysis way?

Why can we get fuel oil from waste tires by using pyrolysis way?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

Some people may know that we can get fuel oil from waste tires by tire pyrolysis plant, but why can we get fuel oil from waste tires by pyrolysis? Now let's find out by looking at the composition of the tire and how the pyrolysis process works.

Tire pyrolysis plant

Tire pyrolysis plant

First, let's look at the composition of tires. The main components of tires are rubber, carbon black and steel wire. About 50% of the ingredients in tires are rubber, which is made from small olefin molecules in petroleum and polymerized at high pressure.

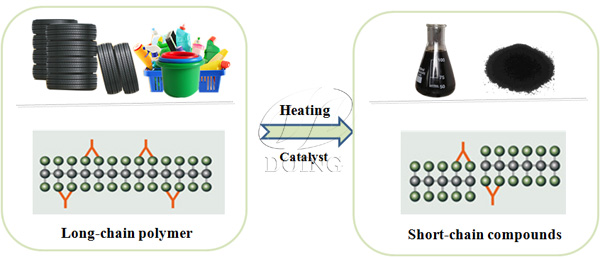

If the rubber is to be turned into oil again, it is necessary to carry out the reverse process of the polymerization reaction of the rubber, so that the large molecules in the rubber are converted into small molecules, and they are reduced to petroleum-based components. Therefore, the waste tires pyrolysis is actually the thermal pyrolysis of waste tires to change their physical form.

Thermal pyrolysis refers to the high-temperature pyrolysis reaction of organic substances in the absence of oxygen. It is a chemical process that can convert one sample (mainly high molecular compounds) into several other substances (mainly low molecular substances). The essence of pyrolysis is to heat up organic macromolecules and crack them into small molecules to separate out. In this process, the reactions carried out in different temperature ranges are different, and the product composition is also different.

Pyrolysis principle

Pyrolysis principle

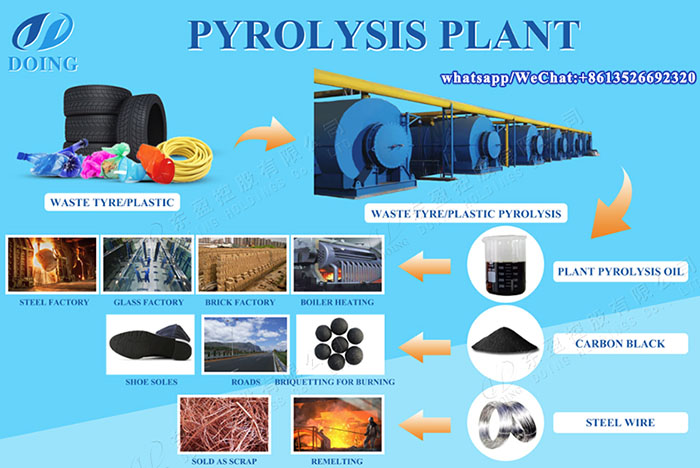

So the thermal pyrolysis of waste tires refers to the rupture of the main chain and unsaturated bonds in the rubber under the condition of oxygen-free or oxygen-deficient conditions and the appropriate temperature. The products are mainly monomers, dimers and fragments, and the products are polymerized. It is a process of removing volatile substances from various olefins and forming solid carbon. The waste tires are treated to produce four by-products: fuel oil, carbon black, steel wire and non-condensable gas. Fuel oil, carbon black and steel wire can be directly sold as products to downstream companies for use, and the non-condensable gas is purified and recycled as the heating fuel for the pyrolysis reactor.

Final products and their applications from tire pyrolysis plant

Final products and their applications from tire pyrolysis plant

Our company's tire pyrolysis plant adopts low-temperature and micro-negative pressure cracking technology without adding any catalyst, which can improve the efficiency of thermal pyrolysis, ensure the safety of the production process, and control environmental pollution emissions.

If you want to know more details about our tire pyrolysis plant, please contact us for free.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications