Tyre Pyrolysis Plant Project Report

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

Background and Significance of Tyre Pyrolysis Plant

Behind the rapid economic development, the problem of environmental protection is increasingly prominent. Especially the waste tyres, the mountains of waste tyres not only occupy a lot of land, but also seriously pollute the living environment of human beings. The United States reportedly dumped more than 2 million used tyres into the ocean to decompose, only to pay a heavy price 50 years later. Therefore, it is very important to find the right treatment method. According to the practical needs, DOING company has developed an efficient method of recycling waste tyres- tyre pyrolysis plant. The following is the tyre pyrolysis plant project report.

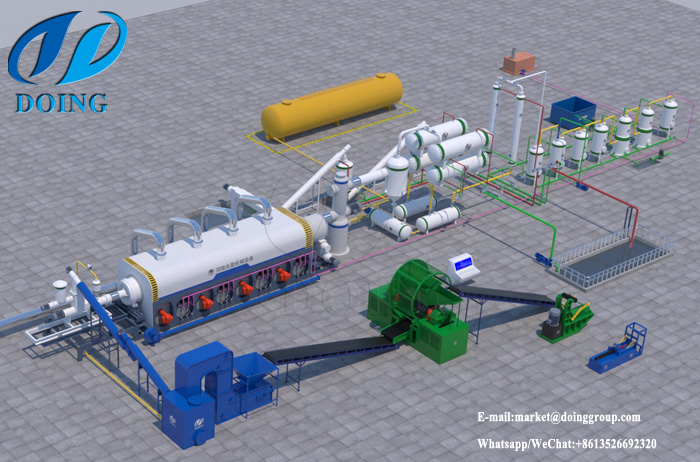

DOING tyre pyrolysis plant

DOING tyre pyrolysis plant

Unique Advantages of DOING Tyre Pyrolysis Plant

1. Safety, environmental protection and simple operation

Firstly, the tyre pyrolysis plant developed and manufactured by DOING company is equipped with oil and water separator, vacuum device, water seal and other safety devices to ensure the safety of the tyre pyrolysis plant during normal operation.

Secondly, in order to achieve the purpose of environmental discharge, the tyre pyrolysis plant of DOING company adopts waste water pollution control and waste gas pollution control and other treatment systems respectively in the treatment of waste water and waste gas, so as to make the discharge standard and no pollution to the environment.

Finally, our tyre pyrolysis plant is easy to operate, only two people per shift can operate the tyre pyrolysis plant, saving manpower.

2. High oil yield.

As a professional tyre pyrolysis plant manufacturer with 10 years of operation, DOING company adopts a unique three-stage cooling system to improve the oil yield of waste tyres. The three-stage cooling system, also known as the heat exchanger, is the most widely used condenser with the best cooling effect in the oil and grease industry. After the treatment of the three-stage cooling system, the pyrolysis oil and gas can be fully cooled and the oil yield can be increased.

3. Various models are available

To meet the needs of different customers, our tyre pyrolysis plant has been designed in a variety of models.

Small tyre pyrolysis plant (DY-S-100, DY-S-500) can be used to test the oil yield of raw materials, and some schools are used for theoretical research.

In addition, we also provide 10 tons, 12 tons, 15 tons of tyre pyrolysis plant, these large processing tyre pyrolysis plant, can be used for mass production, efficient recycling of waste tyres.

12T tyre pyrolysis plant

12T tyre pyrolysis plant

If your budget is adequate, consider the continuous tyre pyrolysis plant. This kind of pyrolysis plant although the price is a little higher, but can achieve continuous feeding, continuous discharge of slag, the whole process adopts automatic control, and can save manpower.

Continuous tyre pyrolysis plant

Continuous tyre pyrolysis plant

In addition, we can customize the tyre pyrolysis plant according to your requirements.

Operation Process of tyre pyrolysis plant

DOING tyre pyrolysis plant USES advanced pyrolysis technology to transform waste tyres into useful resources: fuel oil, carbon black, steel wire, etc. The following is the operation of the tyre pyrolysis plant.

Tyre pyrolysis plant production line

Tyre pyrolysis plant production line

1. Check the motor to make sure it can work normally. Then open the feed port and load. With the automatic feeder, two workers are required to operate the feed, which lasts about 1-1.5 hours. After feeding, close the door of feeding port and slag discharge port to ensure the door is well sealed.

2. Turn on the burner for heating, and at the same time turn on the draught fan of the soot system;

3. Check the thermometer and record the temperature regularly. When the temperature reaches 160 degrees, use the gas spray gun to check whether there is oil and gas coming out.

4. Continue to heat, so that the temperature is controlled at 200-300 degrees. This stage is the oil-producing stage, and the duration is about 4 hours.

5. Keep heating until the temperature drops to about 150 degrees. Stop heating and turn off the machine.

6. After the machine is parked for 2 hours, open the carbon black slagging port and rotate the reactor for slagging. The slagging process will take about 1.5-2 hours.

7. Open the feed door and pull out the steel wire.

Basic technical parameters of tyre pyrolysis plant (Batch Type)

| No. | Items | Contents | ||

| 1 | Equipmenttype | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Rawmaterial | Waste tyres | Waste tyres | Waste tyres |

| 3 | Structuralform | Horizontalrotation | Horizontalrotation | Horizontalrotation |

| 4 | 24-hourCapacity | 6ton | 10ton | 12ton |

| 5 | Oilyield | 2.7-3.3ton | 3.6-4.4ton | 4.5-5.5ton |

| 6 | Operatingpressure | Normal | Normal | Normal |

| 7 | MaterialofpyrolysisReactor | Q245R | Q245R | Q245R |

| 8 | ThicknessofpyrolysisReactor | 16mm | 16mm | 16mm |

| 9 | RotatespeedofpyrolysisReactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Totalpower | 19KW | 19KW | 19KW |

| 11 | Modeofcooling | Watercooling | Watercooling | Watercooling |

| 12 | Coolingareaofcondenser | 100sqm | 100sqm | 100sqm |

| 13 | Kindoftransmission | Internalgeardrive | Internalgeardrive | Internalgeardrive |

| 14 | NoisedB(A) | ≤85 | ≤85 | ≤85 |

| 15 | SizeofReactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Workingform | Intermittentoperation | Intermittentoperation | Intermittentoperation |

| 17 | Deliverytime | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

The main components of the tyre pyrolysis plant

| 1. Pyrolysis Reactor | |

|

The pyrolysis reactor is the main part of the tyre pyrolysis plant. The pyrolysis reactor is made of 16mm thick boiler plate, which can withstand high temperature and high pressure. The tyre pyrolysis plant of DOING company adopts a 360-degree rotary furnace, which can evenly heat the raw material, improve the oil yield and extend the service life of the pyrolysis reactor. |

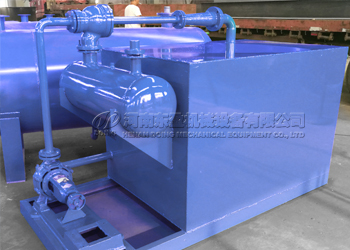

| 2. Vacuum Device | |

|

After the completion of pyrolysis, the vacuum device can be used to drain the residual oil gas in the reactor, accelerate the cooling of the reactor, and ensure the slag discharge process is safe and odor free. |

| 3. The Condenser | |

|

The tyre pyrolysis plant of DOING company adopts a three-stage cooling system, all of which are horizontal and vertical condensing structures. The two kinds of condensing combination can achieve the best condensing effect and improve the oil yield. |

| 4. Carbon Black Discharge Device – Wind Conveying System | |

|

We adopt the way of side slagging, and the carbon black produced can be discharged automatically through the carbon black discharge device. the operation process is simple, but also pollution-free to the environment. |

| 5. Tail Gas Cleaning and Odor Removal System | |

|

It is mainly used to purify the waste gas produced in the process of production of tyre pyrolysis plant. After the treatment of tail gas cleaning system, H2S gas contained in the exhaust gas can be removed, and some nitrogen oxides and sulfur oxides can be removed, so as to achieve the final emission standard and help customers solve the exhaust gas emission problem. |

Profit Analysis of Tyre Pyrolysis Plant

Some investors may look at the price of the tyre pyrolysis plant and wonder whether the project is profitable at such a large cost. Here's a profit analysis based on the Indian market.

| 10TPD Tyre Pyrolysis Project Profit Analysis(standard configuration,heating by coal) | |||||

| Daily consumption | |||||

| Item | Price(usd) | Quantity(Ton) | Cost(usd) | ||

| Waste tyre | usd100/ton | 10 | 1000 | ||

| Coal | usd70/ton | 0.5 | 35 | ||

| Water&Electricity | 0.26 | 192kwh | 49.92 | ||

| Chemicals | 9 | ||||

| Workers’ salary | 15 | 4 | 60 | ||

| Equipment depreciation | 15 | ||||

| Total: | 1168.92 | ||||

| Daily outcome | |||||

| Item | Output(%) | Price(usd) | Quantity(Ton) | Income(usd) | |

| Tyre furnace oil | 45% | usd500/ton | 4.5 | 2250 | |

| Tyre carbon black | 30% | usd76/ton | 3 | 228 | |

| Tyre steel | 10% | usd150/ton | 1 | 150 | |

| Oil residue | 5% | usd150/ton | 0.5 | 75 | |

| Total: | 2703 | ||||

| Profit | |||||

| Daily profit | Usd1534.08 | ||||

| Monthly profit(based on 20 batches) | usd30681.6 | ||||

| Annual(based on 10 months) | usd 306816 | ||||

In summary, this is the project report of DOING tyre pyrolysis plant. If you are looking for a profitable project, please contact us. DOING's tyre pyrolysis plant can not only process all types of waste tyres into fuel oil, carbon black and steel wire but also can dispose of waste plastic, waste rubber and oil sludge and other raw materials. Our tyre pyrolysis plant has been installed in more than 70 countries and regions around the world.

DOING company also provides high quality after - sales service, and thus obtained a lot of old customers repeat purchase. Are you still hesitating? Please contact us to order as soon as possible.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications