Waste tyre pyrolysis plant

Waste tyre pyrolysis plant

The waste tyre pyrolysis plant can turn these waste into treasure through the high temperature heating, distilling the oil gas, condenser system, and dedusting system. These wastes can be converted into high-value new resources such as fuel oil, carbon black, and steel wires.

Waste tyre pyrolysis plant

In the process of pyrolysis, due to the long-term operation or the other conditions, for example, the excessive fouling and the aggravated erosion possibly cause the machine breaking down.If you have steel wire drawing machineand waste tyre shredder to deal the waste tires before feeding them into reactor,it will be better for your reactor and reduce the steel wire from waste tires damage to your reactor!More detail information about the waste trye pyrolysis plant are as follows:

Waste tyre pyrolysis plant working process

Feeding the raw material into the reactor by manual or auto feeder, then fire the fuel to heat the reactor. After the temperature increase to relevant degree, the oil gas will be generated and enter the gas separator. Here, the heavy components will be liquefied and drop into the heavy oil tank. And light oil gas will rise into the oil condenser being liquefied and get into the oil tank. The unliquefied combustible gas enter the hydroseal , in here , after desulfuration and purification, one part of it will be recycled to heat the reactor, another part will be burn out to reduce the pressure while the pressure is too high.

Waste tyre pyrolysis plant main advantages

1. Safe. The tyre/plastic pyrolysis plant is equipped with mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee 100% safety in the pyrolysis process.

2. Energy-saving. By the extra gas recycling system, the gas that can not be condensed will be recycled to the burning room. It can replace the fuel material to heat the reactor, which will reduce additional fuel consumption.

3. Environment friendly. In the de-dusting system, three steps (water spray, ceramic ring filter, washing chamber) are used to dedust the extra gas and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly.

Waste tyre pyrolysis plant final product application

Fuel oil application

1.Fuel Oil (45% to 52%)

The main application of oil products produced by our Waste tyre pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Carbon black application

Steel Wire (12% to 15%) Waste tyre pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

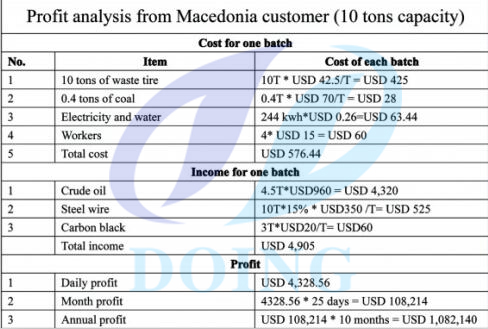

After the basic introduction of the waste tyre pyrolysis plant,most people may want to know about the profits analysis of this equipment.Following is the specific profits of this equipment.

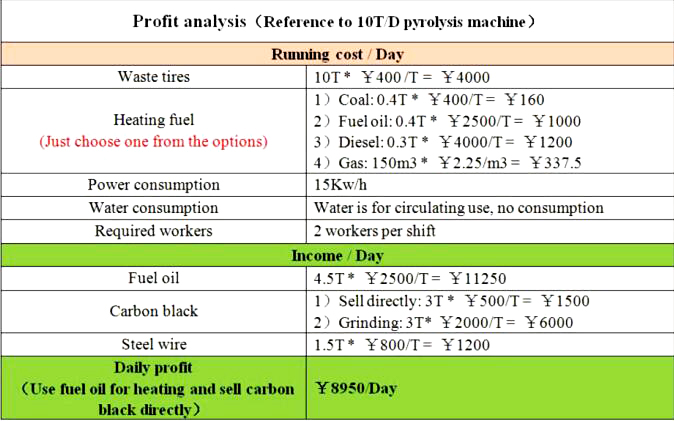

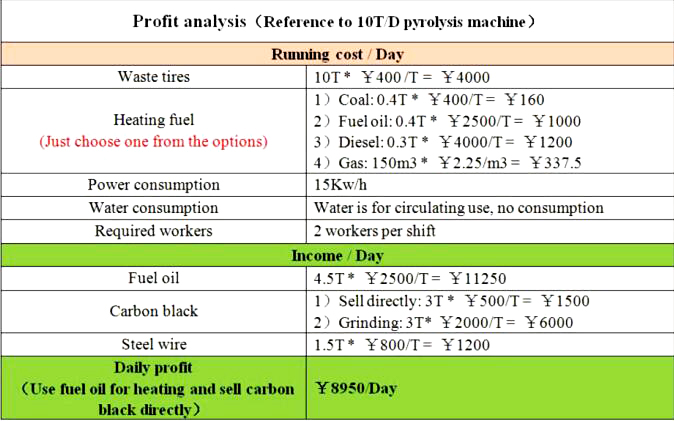

10T waste tyre pyrolysis plant profits analysis in our country

Macedonia customer visited our factory 3 times

The people marked with red line in the photo are our old customer Mr Victor and Mr Gauden from Macedonia. In the last years, they came to China 3times for our DOING waste tyre pyrolysis machine. Their first visit was in July 2011 when they started the tyre recycling to oil business by giving the 1st trial order to us. With the annual profit around USD1,000,100.00, they made a visit to us in December 2012 and October 2014 for the second and third order.After the basic introduction of the waste tyre pyrolysis plant,most people may want to know about the profits analysis of this equipment.Following is the specific profits of this equipment.

10T waste tyre pyrolysis plant profits analysis in our country

Of course in different country the profits is not all the same,the above profits analysis is just in our country.

Macedonia customer visited our factory 3 times

Macedonia customer's 10T waste tyre pyrolysis plant

They are very satisfied with our waste tyre pyrolysis plant and send us the profits analysis in their country for your reference!