5Th generation tyre pyrolysis continuous plant

5Th generation tyre pyrolysis continuous plant

5Th generation tyre pyrolysis continuous plant working process is a thermophilic anaerobic treatment technology. The whole work process can be briefly introduced from six parts.

Tyre continuous pyrolysis plant working process

Secondly, the steel wire in the scrap tire is drawn out with a wire drawing machine.

Again, the tire with the wire removed was broken with a tire crusher.

From then on, through the sealed screw conveyor, scrap tire fragments will be transported to the reactor for higher temperature pyrolysis.

Finally, as the reactor temperature increases, hydrocarbons and carbon black are produced in the pyrolysis furnace. Carbon black can be directly collected and the gas rises into the manifold under the effect of the gas flow. At this stage, oil and gas will also be divided into two parts based on weight. The weight falls directly into the heavy tank and light gas enters the manifold for further processing.

In addition, the obtained heavy oil gas is desulfurized and degreasing.

Through this 5Th generation tyre pyrolysis continuous plant process we can finally get fuel, carbon black, steel wire, and combustible gas. Their purpose is as follows:

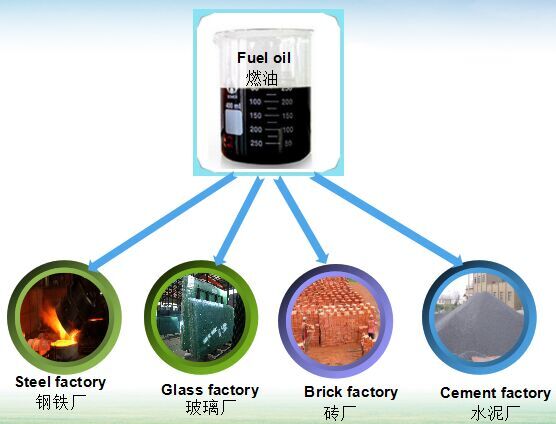

Fuel oil application

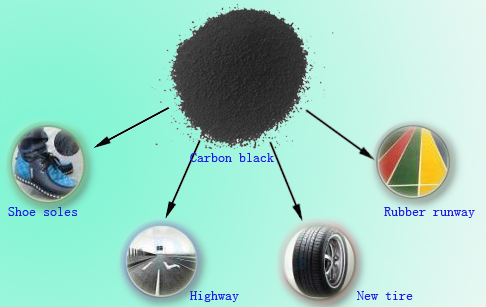

Carbon black application

3. Steel wire: mainly used for waste recycling or sent to the steel plant to recast.

4. Combustible gas: It will be recycled by the equipment and used for the heating material of the reactor.

The 5Th generation tyre pyrolysis continuous plant has the following advantages:

DoingGroup'S continuous pyrolysis plant

Safety is of paramount importance for continuous or batch waste tire recycling plants.

First, we have special safety devices such as safety valves, thermometers, pressure values, water seals, oil-water separators, etc.

Second, we have strict testing equipment from raw materials to machine production.

2. Environmental protection

The continuous waste tire recycling and recycling plant can recycle waste tires and can not only protect the waste tires from pollution, but also bring profits.

We have a professional water removal system for 5Th generation tyre pyrolysis continuous plant.

3. High degree of automation

The 5Th generation tyre pyrolysis continuous plant can continuously supply raw materials and discharge carbon black. The entire system is controlled by a PLC with a high degree of automation.

The 5Th generation tyre pyrolysis continuous plant is the replacement of continuous tire cracking equipment by DoingGroup. With a high degree of automation and improved sealing performance, your investment is the best choice!