Tyre derived fuel oil recycling plant

Tyre derived fuel oil recycling plant

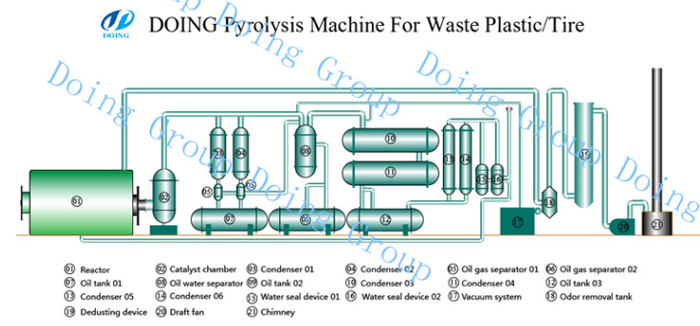

The tyre derived fuel oil recycling plant can effectively convert waste tire into fuels, like Oil, Carbon Black, and Hydrocarbon Gas etc. Here, the raw material is either waste tire or waste plastic. Then, the recycleables are heated from the reactor to be able to generate fuels, oil, and gas.

Tyre derived fuel oil recycling plant wroking process

Tyre derived fuel oil recycling plant wroking process

Second, start the pyrolysis plant reactor will rotating and be heated. When the inside temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460.

Third, in oil gas separator, light component will enter the condensers, meanwhile, heavy component will be liquefied and then automatically discharged into heavy oil tank.

Forth, most of the light component will be liquefied through condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning.

Tyre derived fuel oil recycling plant advantage

Tyre derived fuel oil recycling plant

2.On an average, the entire pyrolysis process may lead to a yield of around 45-52% oil, 30-35% charcoal, and 15% gas. The oil produced is mainly made up of diesel, kerosene, benzene, fuel oil & heavy fuel oil. Hence, the produced oil may be further refined and useful for operating any vehicle.

3.The plant pollution has truly get to be the most problem nowadays. Obviously, tyre derived fuel oil recycling plant give you a meaningful strategy to it while promoting an eco-friendly solution by reduction of the hazards of land pollution due to the waste tire.

4.By converting the waste into energy,the tyre derived fuel oil recycling plant offers an alternative energy source too.

Tyre derived fuel oil recycling plant final product application

Fuel Oil

Fuel oil application

Carbon Black

Carbon black application