Carbon black from waste tyre to fuel oil pyrolysis plant

Waste tyre to fuel oil pyrolysis plant

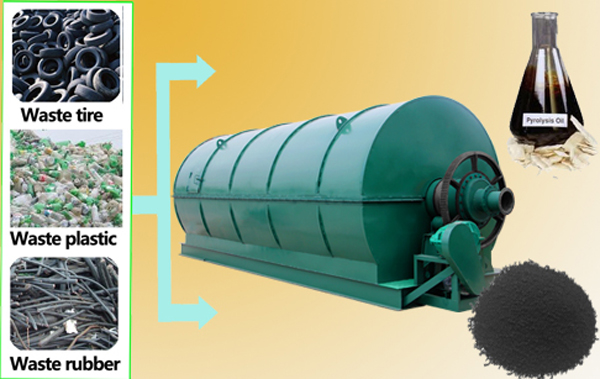

DOING revolutionary waste tyre to fuel oil pyrolysis plant can really convert waste tyre into wealth. How is it possible? Because from waste tyre, you can get fuel oil, carbon black and reclaim the steel wire. Tyre fuel oil, tyre carbon black and tire wire all can bring you handsome profit. Today I am writing to mainly elaborate the application of carbon black from DOING waste tyre to fuel oil pyrolysis plant.

From the table below you can see the end products got from our waste tyre to fuel oil pyrolysis plant and their respective usage. Carbon black is the second main product from waste tyre to fuel oil pyrolysis plant. So it is very important to know the market of the carbon black from waste tyre to fuel oil pyrolysis plant.

The end products from waste tyre to fuel oil pyrolysis plant:

| NO | Carbon black from waste tyre to fuel oil pyrolysis plant Name | Percentage(%) | Usage |

| 1 | Tyre oil | 40~45 | * can be sold directly. |

| * can be as fuel. | |||

|

2 |

Carbon black | 30~35 | * can be sold directly. |

| * Process into pellets used for industrial heating or make fine carbon by use carbon black refiningmachine. | |||

| 3 | Steel wire | 12~15 | can be sold directly. |

| 4 | Sync gas | 5 | * can be recycled as auxiliary heating fuel |

Carbon black as the second main product of waste tyre to fuel oil pyrolysis plant also has a very high industrial value.The carbon black produced by the pyrolysis process could be sold to the market ,also could be further processed before selling.At present,there are mainly 2 processing ways for carbon black.One is briquetting ,the other one is grinding.

Carbon black application

1.Briquetting

Carbon black briquetting

After testing ,the combustion value of the pyrolysis carbon black could reach to 7000Kcal/kg,which is almost equal to coal and charcoal,then after briquette the carbon black into pellets,it could be directly used for industrial heating instead of coal.This way ,it could promote the use value of the carbon black,also could reduce the use cost of the heating fuel.

2.Grinding

Carbon black grinding

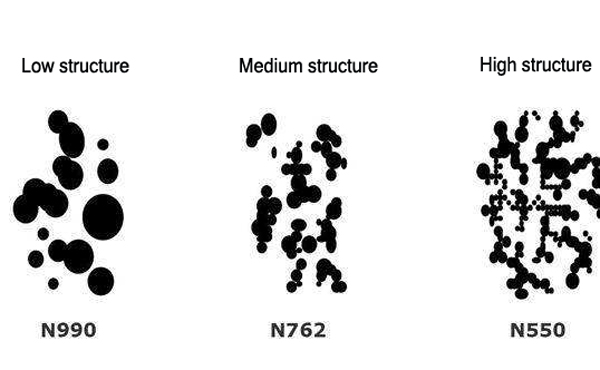

Due to the special raw material and production process,the pyrolysis carbon is also different from the normal carbon black.The pyrolysis carbon black is crude ,and the ash content is high ,but has more oily material on surface,which makes it has very similar physical and chemical property to the common used semi-reinforced carbon black.

Different mesh carbon black

Based on this advantage,we could make further refining for the pyrolysis carbon black to get N990,N762,N550 and other semi-reinforced carbon black ,which could be used for making many kinds of rubber products .In addition,the carbon black grinding process could be made in sealed system,which could avoid secondary pollution to the aie ,and promote the use value of the carbon black.The pyrolysis carbon black after refining could be sold as 292-438USD per ton,which could bring much higer profit to the user.

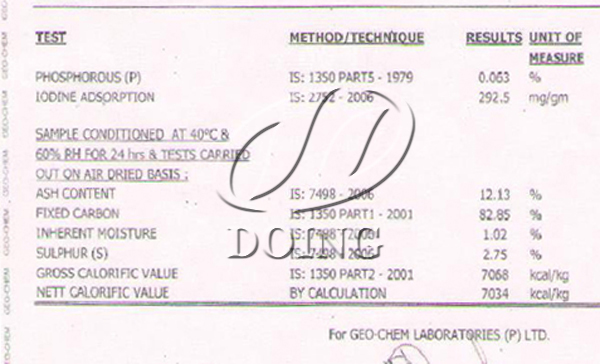

Below is the testing report of carbon black from waste tyre to fuel oil pyrolysis plant:

Testing report of carbon black

Through this report, you can refer to the content of carbon black components from waste tires to fuel oil pyrolysis plants, this report is just for your reference!