Home>Product> Waste Plastic Recycling Pyrolysis PlantThe latest generation of turning plastic into oil machine

Home>Product> Waste Plastic Recycling Pyrolysis PlantThe latest generation of turning plastic into oil machine

The latest generation of turning plastic into oil machine

Waste Plastic Recycling Pyrolysis Plant / Chat online / Give me a price

The latest generation of turning plastic into oil machine, expertly produced by DOING company, represents the pinnacle of years of dedicated research and development, directly informed by invaluable customer feedback. This advanced fully continuous plastic to oil pyrolysis machine is engineered to efficiently and environmentally transform waste plastics into valuable fuel oil and high-quality carbon black.

Turning plastic into oil and carbon black continuous pyrolysis machine

Turning plastic into oil and carbon black continuous pyrolysis machine

Essential Continuous Plastic Pyrolysis Equipment Specifications

DOING’s fully continuous plastic to oil pyrolysis machine is available in various configurations to suit different production needs. Typical specifications include:

Processing Capacity: Ranging from 15 ton/day to 50 tons/day per set, with larger custom solutions available.

Reactor Material: High-temperature resistant steel alloy (e.g., Q245R, Q345R) for enhanced durability and longevity.

Reactor Dimensions: Varies based on capacity, but designed for optimal heat transfer and material flow.

Cooling System: Advanced multi-stage vertical cooling condensers for maximum oil recovery and condensation efficiency.

Heating Method: supplemented by external heat sources in the first stage and then primarily uses the combustible gas generated during pyrolysis for self-heating.

PLC Control System: Automated control for precise temperature, pressure, and process monitoring.

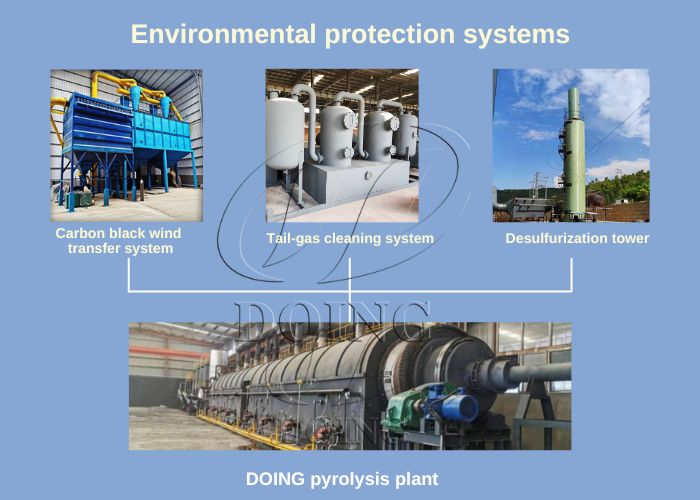

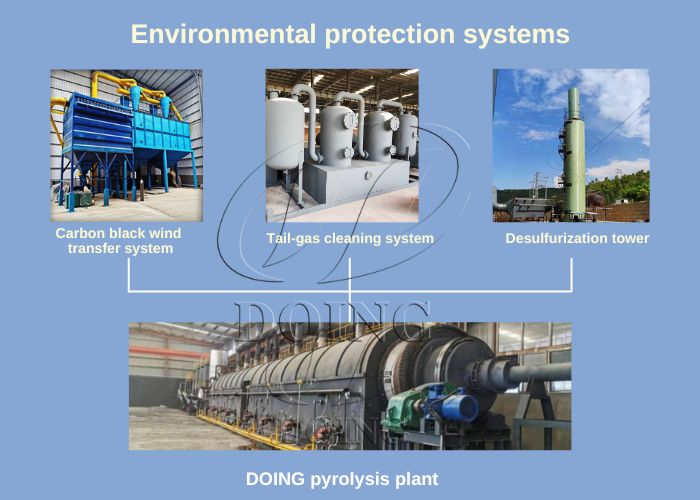

Flue Gas Treatment System: Integrated multi-stage exhuast gas purification and desulfurization system (e.g., water scrubbing, activated carbon filtration) to ensure emissions meet national standards.

Our latest innovation moves beyond traditional batch processing. The fully continuous plastic to oil pyrolysis machine design ensures uninterrupted operation, significantly boosting processing capacity and reducing downtime. This continuous workflow means greater throughput, optimized energy utilization, and a more streamlined and profitable recycling operation.

The latest generation of turning plastic into oil machine

The latest generation of turning plastic into oil machine

The Main Workflow of Our latest Generation of Turning Plastic into Oil Machine

1. Automated Feeding: crushed small plastic pieces are efficiently and continuously fed into the reactor via an automatic feeding system, ensuring a consistent material flow.

2. Preheating and Gasification: The reactor is rapidly and precisely heated, initiating the pyrolysis process and generating oil gas.

3. Continuous Pyrolysis: The plastic pyrolysis reactor maintains optimal temperatures for the complete decomposition of plastic into oil and gas, usually 220-500°C.

4. Efficient Cooling and Collection: Separated oil gas is directed to an advanced cooling system, where it condenses into liquid fuel oil and is collected in a secure storage tank.

5. Gas Recovery: Any uncooled combustible gas is recovered and can be reused for heating the reactor, further enhancing energy efficiency.

6. Emissions Control: Flue gas produced during the process undergoes rigorous treatment via an integrated flue gas purification system, ensuring discharged emissions comply with national environmental standards.

7. Carbon Black Discharge: The generated high-quality carbon black is safely discharged through auto-discharger.

Workflow of the latest generation of turning plastic into oil machine

Workflow of the latest generation of turning plastic into oil machine

Key Advantages of the Latest Generation of Continuous Plastic to Oil Pyrolysis Machine

Compared to previous models and conventional methods, our latest generation of plastic to oil pyrolysis machine offers a superior recycling solution with the following distinct advantages:

High Efficiency and Yield: Experience a dramatic increase in processing efficiency. Our fully continuous tunring plastic into oil machine achieves a significantly higher oil yield than older models. Its highly efficient operation not only shortens working cycles but also drastically reduces labor requirements, with only two or three operators typically needed for seamless management.

Superior Oil Quality: This machine employs the latest technological advancements to precisely control the pyrolysis process. It effectively decomposes long-chain organic matter in waste plastics into shorter chains, resulting in the production of higher quality, more valuable oil products.

Cost-Effectiveness and Enhanced Profitability: The initial investment in our fully continuous plastic to oil pyrolysis machine is remarkably cost-effective, offering exceptional value. Beyond the purchase price, it significantly lowers operating costs and optimizes energy consumption, paving the way for greater profitability and a stronger return on investment.

Environmental Compliance: Leveraging cutting-edge pyrolysis technology and multiple con, this machine processes waste plastics with less pollution. It meticulously meets and exceeds current stringent environmental protection requirements mandated by national and governmental bodies, making it a responsible choice for sustainable waste management.

Environmental devices of plastic into oil pyrolysis processing machine

Environmental devices of plastic into oil pyrolysis processing machineEnhanced Safety Features: The fully continuous plastic to oil pyrolysis machine is equipped with comprehensive safety devices, including precise thermometers, pressure gauges, safety valves, and an advanced electronic control system. Operators can monitor all aspects of the machine’s operation in real-time, guaranteeing a safe and accident-free working environment.

Economic and Environmental Benefits as a Plastic Recycling Solution:

The fully continuous plastic to oil pyrolysis machine offers a compelling dual benefit:

Economic Advantages:

Resource Recovery: Transforms low-value waste plastic into high-value fuel oil(alternative industrial heating fuel) and carbon black, which can be sold for profit or used internally. The plastic generated pyrolysis oil can also be refined into diesel by pyrolysis oil distillation plant.

Plastic pyrolysis oil uses as industrial alternative heating fuel

Plastic pyrolysis oil uses as industrial alternative heating fuel

Reduced Landfill Costs: Diverts plastic waste from landfills, saving on disposal fees and mitigating environmental impact.

Energy Independence: Creates a local source of fuel, reducing reliance on imported fossil fuels.

Environmental Advantages:

Waste Reduction: Directly addresses the global plastic waste crisis by providing a viable method for its conversion.

Pollution Prevention: Eliminates the harmful emissions associated with open burning or improper disposal of plastic waste.

waste plastic recycling solution pyrolysis technology

waste plastic recycling solution pyrolysis technology

Circular Economy Enabler: Promotes a sustainable loop where plastic waste is a valuable resource, not a pollutant.

Lower Carbon Footprint: Compared to virgin plastic production, recycling through pyrolysis significantly reduces greenhouse gas emissions.

Are you looking for a cutting-edge, environmentally responsible, and highly profitable solution for your plastic waste? DOING’s latest generation of fully continuous plastic to oil pyrolysis machines can meet your needs!

For detailed specifications, personalized quotes, or to discuss how our technology can benefit your business and contribute to a cleaner planet, please don’t hesitate to contact us. Leave your inquiry below, and our expert team will get back to you promptly.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

Environmental devices of plastic into oil pyrolysis processing machine

Environmental devices of plastic into oil pyrolysis processing machine