Waste plastic recycling pyrolysis plant is a kind of machine that can dispose of waste plastic into fuel oil. As we all know, waste plastic makes up around 30% of all rubbish collected. This includes plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc. Because the plastic is slow to degrade, this kind of waste is becoming a serious problem. So, solving the plastic pollution has become the imminent thing and is the primary task for people. The best method to dispose the waste is to turn waste into wealth and recycle the resources. Therefore, waste plastic recycling pyrolysis plant is a good choice for recycling waste plastic.

Recycling waste plastics into oil

Recycling waste plastics into oil

Waste plastic recycling pyrolysis plant is magical which is produced by DOING that can make waste plastics into precious oil. It sounds unbelievable, but that is a fact. Now let us explore waste plastic recycling pyrolysis plant together.

The process of waste plastic recycling pyrolysis plant:

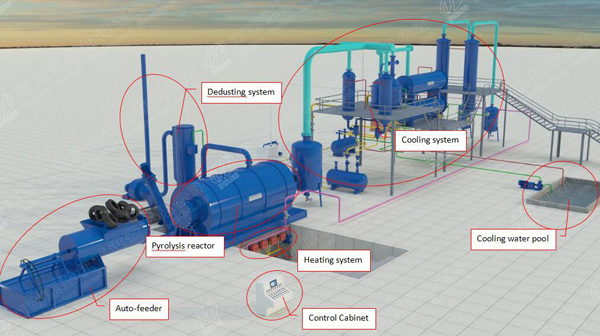

The process of waste plastic recycling pyrolysis plant handing waste plastic is not that complicated. But it should follow specific process and specification. The process of DOING handling waste plastic are as follows:

Waste plastic recycling pyrolysis plant

Waste plastic recycling pyrolysis plant

1. Put waste plastics into a sealed reactor.

2. Heating the sealed reactor that can make macromolecule into small molecule, then waste plastics are pyrolyzed into oil gas, uncondensable gas and carbon black.

3. Cooling. The oil gas can be cooled down to oil which usually be called pyrolysis oil through a water circulating cooling system which is a important part for the waste plastic recycling pyrolysis plant. Pyrolysis oil has many applications, such as be used in steel factory, boiler heating, heavy oil generator, cement factory. Go a step further, the application of pyrolysis oil is refined into diesel. DOING also provide plastic oil to diesel distillation plant. The diesel can be used in diesel generator or heavy machinery or being a diesel fuel for heating. There are great economic benefits for investor.

Pyrolysis oil applications

Pyrolysis oil applications

4. Exhaust gas recovery and utilization. The uncondensable gas is usually recycled to heat the reactor or collected as a fuel. This action reduce air pollution to a great extent. It is good for our life. This is what the government strongly advocates.

5. Discharging carbon black. Carbon black can be made into pellets for burning and heating, or be refined to making new rubber products, for example, making new plastic, shoe soles, paint and so on. In a manner of speaking, these products are everywhere in our life.

Carbon black applications

Carbon black applications

So down, everything has its place. Ensuring that nothing gets wasted is the biggest advantage of this waste plastic recycling pyrolysis plant. The arrival of recycling pyrolysis plant has turned waste plastics into money truly. The most significant aspect of the whole production process is simple and non-pollution. waste plastic recycling pyrolysis plant not only help us handle house refuse to making our living environment better but also provide precious energy ,oil.

The technical data of waste plastic recycling pyrolysis plant:

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Prepared by customer about waste plastic recycling pyrolysis plant

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

As we all know energy is limited, so waste plastic recycling pyrolysis plant is far-reaching significance for us. It will be a future trend for the whole world to use waste plastic recycling pyrolysis plant.