Home>News>Industry NewsWhat is the current situation regarding recycling plastics in Indonesia? What's the solution?

Home>News>Industry NewsWhat is the current situation regarding recycling plastics in Indonesia? What's the solution?

What is the current situation regarding recycling plastics in Indonesia? What's the solution?

Industry News / Chat online / Give me a price / September 19, 2023

Indonesia is one of the countries with serious plastic pollution problems in the world and faces a large number of waste plastic processing and recycling challenges. According to reports, Indonesia produces about 3 million tons of waste plastic every year, of which only about 10-20% is recycled and reused. Therefore, the current situation of waste plastic recycling in Indonesia is quite severe, but the prospects for waste plastic processing and recycling are relatively promising.

1. The governmental support

At present, the Indonesian government has taken a series of measures to promote the development of the plastic recycling industry. For example, the government has enacted some regulations that require manufacturers and consumers to be responsible for recycling and handling waste plastic products. In addition, the government has provided some subsidies and incentives to encourage enterprises and individuals to invest in the plastic recycling industry.

The waste plastic recycling situation in Indonesia

The waste plastic recycling situation in Indonesia

2. Public awareness and education

The Indonesian government efforts are being made to raise public awareness about the importance of recycling and the proper disposal of plastic waste. Education campaigns are being conducted to encourage citizens to participate in recycling initiatives. With the improvement of people’s awareness of environmental protection, the prospects of the plastic recycling industry are becoming more and more broad.

3. The development of plastic recycling technology

There is a growing focus on innovation and research to find alternative materials to plastic, as well as new recycling technologies that can improve the efficiency of plastic recycling processes. Among the many plastic recycling technologies, the plastic pyrolysis recycling technology has become an effective solution to the recycling of waste plastics in Indonesia with its advantages of sustainable utilization, resource conservation, environmental protection, and efficient utilization.

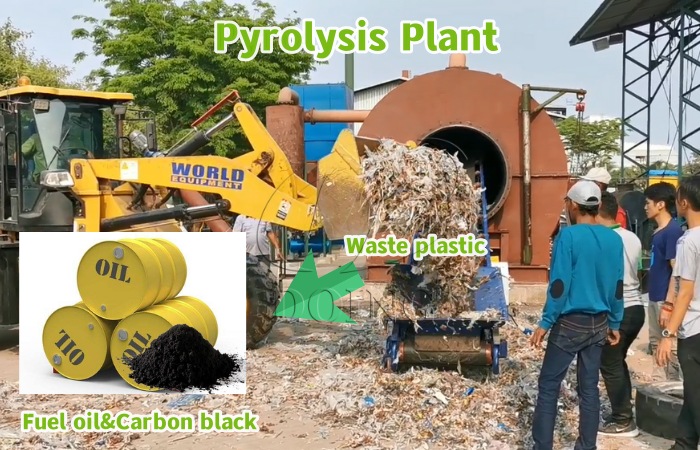

DOING waste plastic pyrolysis plant

DOING waste plastic pyrolysis plant

Waste plastic pyrolysis technology is a technology that breaks waste plastic molecules under low temperature and atmosphere to form smaller oil molecules. DOING waste plastic pyrolysis plant uses this technology to convert waste plastics into high value-added energy products such as fuel oil, carbon black, and combustible gases.

The core process of DOING waste plastics pyrolysis plant is anaerobic cracking. By sealing the waste plastic in an oxygen-free reactor and heating it, it decomposes into small molecular organic volatiles (oil-gas) and inorganic coke black. Then it is equipped with a condensation system to cool the oil gas into liquid oil.

The uses of plastic fuel oil

The uses of plastic fuel oil

This liquid oil with high heating value(10592.48kcal/kg), and it's a kind of very good heating fuel and can be used for many industrial factories, like boiler, cement factories, steel factories, glass factories etc. and it can also be further refined by DOING pyrolysis oil distillation plant and used for diesel combustion engines or heavy machinery; the carbon black can also be used twice in the industrial field. For instance, finely ground carbon black can be used as a raw material for making rubber soles, tires, and pigments.

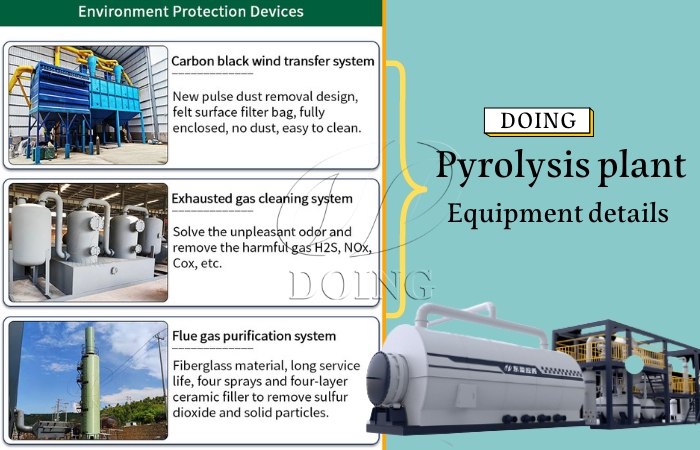

Besides, DOING plastic pyrolysis plant is also equipped with environmental protection devices to ensure no air, water and dust pollution, truly realizing resource conversion and utilization while protecting the environment.

The environment protection devices of DOING pyrolysis plant

The environment protection devices of DOING pyrolysis plant

From the above content, you may have known about the current situation regarding recycling plastics in Indonesia and an effective solution to the recycling of waste plastics --- pyrolysis plant. If you would like to know more information about our waste plastic pyrolysis plant, please feel free to contact Doing's professional sales managers.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications