How do you recover fuel oil from waste oil sludge?

Industry News / Chat online / Give me a price / July 18, 2023

Waste oil sludge is divided into three forms. They are solid, semi-liquid and liquid waste oil sludge. According to different forms, there are mainly 2 ways to recover fuel oil from waste oil sludge. The following takes DOING oil sludge treatment plants as an example to introduce two different waste oil sludge recovery processes.

ⅠSolid&semi-liquid waste oil sludge recovery process

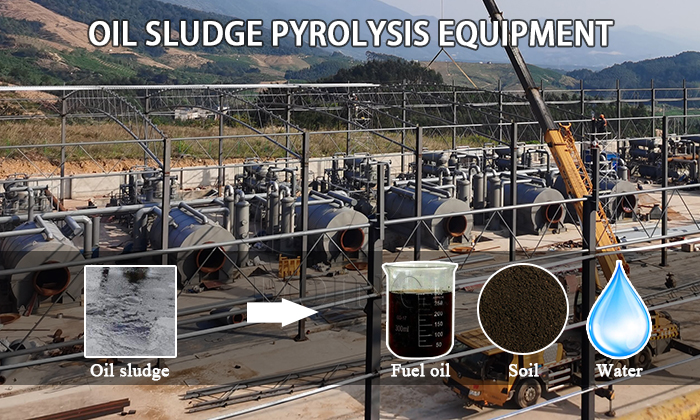

For the solid and semi-liquid waste oil sludge, DOING's oil sludge pyrolysis plant can effectively recover pyrolysis fuel oil from it. Commonly speaking, the oil yield of pyrolysis fuel oil from waste oil sludge is about 40% to 60%.

The recovered pyrolysis fuel oil is a high calorific value heating fuel and can be used for industrial and commercial purposes, such as boiler factory, cement factory, glass factory and power factory, etc.

DOING oil sludge pyrolysis plant

DOING oil sludge pyrolysis plant

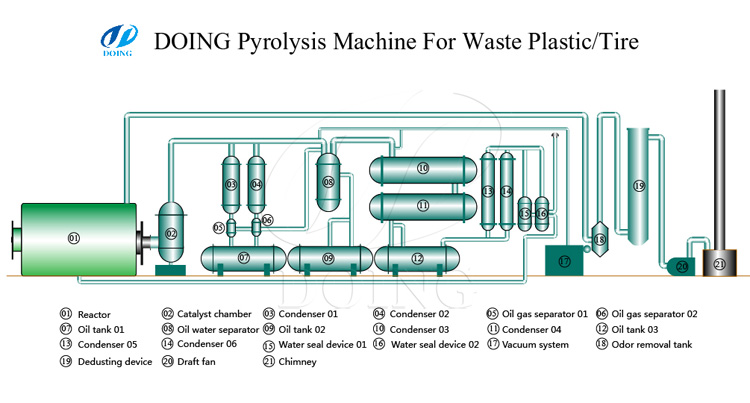

The main process is as follows:

1. Feeding: Feeding the solid or liquid waste oil sludge into the reactor by automatic feeder or lifting auger

2. Heating: Heating the reactor, by high temperature pyrolysis, the waste oil sludge can convert into oil gas and carbon black.

3. Cooling: After the oil and gas are condensed by the condenser, the fuel oil and gas are separated

4. Collection:

Fuel oil can be collected by the oil tank;

The combustible gas is transported to the reactor to heat it;

The non-combustible gas is discharged through the desulfurization tower and the tail gas treatment system;

The recovery process of solid&semi-liquid waste oil sludge

The recovery process of solid&semi-liquid waste oil sludge

Ⅱ Liquid waste oil sludge recovery process

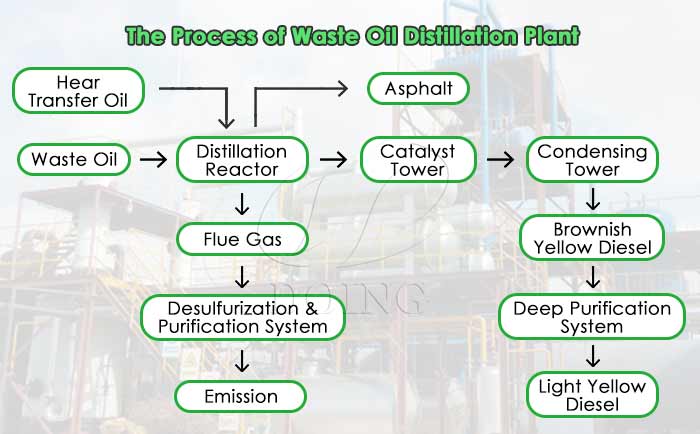

For the liquid waste oil sludge, DOING has oil sludge distillation plants to recover diesel fuel from it. The obtained diesel fuel can be used in heavy machinery, generator, boiler, etc. And the diesel yield mainly depends on the moisture content of the liquid oil sludge.

DOING oil sludge distillation plant

DOING oil sludge distillation plant

Here are the general steps involved in the waste oil sludge recovery process:

1. Feeding: The liquid sludge can be directly pumped into the distillation plant through the oil pump;

2. Distillation: The reactor is heated by a heat conduction oil furnace or burners to a certain temperature, and then produces oil and gas.;

3. Catalysis&Purifying:

The oil and gas are purified by the catalytic tower, and then cooled into liquefied oil by the condenser;

The combustible gas is transported to the reactor to heat it;

The non-combustible gas is discharged through treatment;

The recovery process of liquid waste oil sludge

The recovery process of liquid waste oil sludge

4. Decolorization&deodorization

The liquefied oil is decorated by white clay, the color becomes translucent, and then filtered through the leaf filter to out excess impurities;

5. Storage: Collect diesel oil to tanks for future use as a fuel source or sell.

The above is the introduction of DOING's oil sludge treatment method and process of recovering fuel oil from waste oil sludge.

As an experienced manufacturer of oil sludge treatment plant, DOING has mature technology. No matter which forms of waste oil sludges you want to recycle and recover fuel oil from it, our sales can offer more details and the best suggestion according to your requirement. We have different scales and configurations of oil sludge pyrolysis plant and oil sludge distillation plant for you to choose from!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications