How to choose a high performance plastic recycling pyrolysis plant?

Industry News / Chat online / Give me a price / November 19, 2020

When choosing plastic recycling pyrolysis plant, it is necessary to shop around for high performance and high quality pyrolysis plant. But what should be considered seriously is not only the cost of the plastic recycling pyrolysis plant. You should consider the following aspect.

Plastic recycling pyrolysis plant

Plastic recycling pyrolysis plant

1. Environmental protection of plastic recycling pyrolysis plant

At present, there are many cheap plastic recycling pyrolysis plants in the market, but some of them lack the corresponding environmental protection configuration, which will lead to odor, black smoke and dirty during the operation. Now, DOING company recommends choose plastic recycling pyrolysis plant with environmental protection configuration. The following is the environmental protection configuration from DOING Company. They are mainly tail gas cleaning and odor removal system, desulfurization & purification tower, carbon black lifting machine, etc. After being treated by these devices, the final gas discharged from plastic recycling pyrolysis plant can meet environmental standards.

DOING environmental protection configuration for plastic recycling pyrolysis plant

DOING environmental protection configuration for plastic recycling pyrolysis plant

2. Oil yield of plastic recycling pyrolysis plant

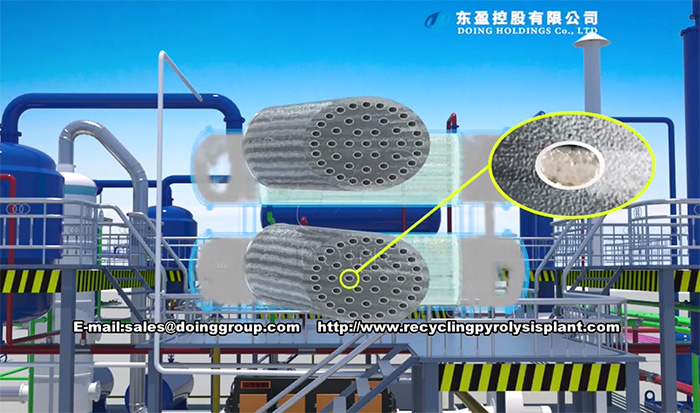

Because fuel oil is the main product of plastic recycling pyrolysis plant, so all investors want to buy equipment with high oil yield. While the oil yield of plastic recycling pyrolysis plant is mainly influenced by the pyrolysis process and the effect of cooling system. So when you choose the plastic recycling pyrolysis plant, you can learn the pyrolysis process and the effect of cooling system. For example, the plastic recycling pyrolysis reactor of DOING adopts a rotating design, which can uniformly heat and ensure the full pyrolysis of waste plastics. Our cooling system of plastic recycling pyrolysis plant are designed with three-stage condensers to ensure adequate cooling of oil gas and ensure the highest oil yield. So professional manufacturers are working on pyrolysis processes and condensing systems to improve the oil yield of their plastic recycling pyrolysis plant.

Cooling system of plastic recycling pyrolysis plant

Cooling system of plastic recycling pyrolysis plant

3. Service life of plastic recycling pyrolysis plant

Investors all hope plastic recycling pyrolysis plant they bought have a long service life. While the service life of plastic recycling pyrolysis plant mainly depends on the manufacturing material and the manufacturing process. For example, the plastic recycling pyrolysis plant of DOING company adopts pressure-resistant and high-temperature steel and three-step welding process, and the plastic pyrolysis reactor manufactured by DOING company can have a long service life. So you when you choose the plastic recycling pyrolysis plant, you can learn the manufacturing material and the manufacturing process to judge the service life.

Manufacturing materials and the manufacturing process of plastic recycling pyrolysis plant

Manufacturing materials and the manufacturing process of plastic recycling pyrolysis plant

Regardless of the price difference in the market, the first you must consider is the above points when choosing plastic recycling pyrolysis plant. It will help you to buy a high performance plastic recycling pyrolysis plant with a reasonable cost. If you want to know more about the pyrolysis plant, please contact DOING.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications