Waste tyre disposal

Industry News / Chat online / Give me a price / November 25, 2014

Waste tyre disposal:

Landfills/ deposits Currently the waste tyres processing in the world is still landfill or deposits, especially in some developing countries about 65% to 70%. This old method is not only take up lots of land area, but also can cause firs release toxic and hazardous gases, can easily become a breeding ground for mosquitoes brought epidemics and caused great harmful to the environment and human health.

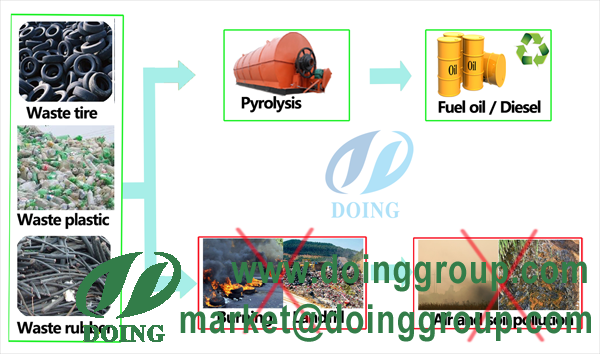

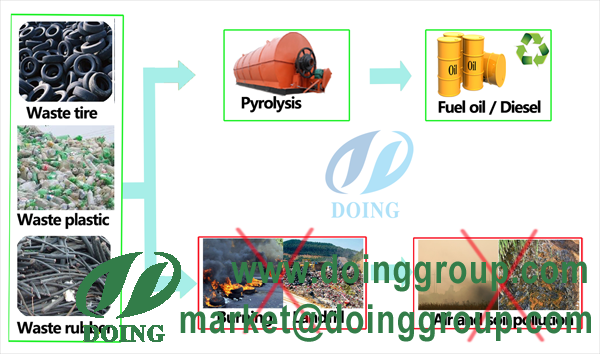

Pyrolysis Waste tyre pyrolysis processing technology is adopt of a variety of industrial waste oil combustion heat generated fumes or electric heating devices, in the absence of oxygen or inert atmosphere pyrolysis the waste tyres, to get fuel oil with a high calorific value, rich in aromatics oil and valuable chemical products such as carbon black, which is a new way of processing the waste tyres. Pyrolysis includes three technology, oil technology, gasification and carbonization technology. In the pyrolysis reactor, the temperature is about 80 ~ 600 ℃ to pyrolysis process waste tyres to produce crude oil, and carbon black mixture. After further purified canning with liquefied petroleum gas, pickling mixture of oil, soda, after washing and white clay adsorption can be obtained by distillation of various petroleum products (such as solvent oil, aromatic oil, diesel, etc.); coarse charcoal after coarsely crushed black after magnetic separation and second grinding, magnetic separation and air separation step, various carbon black particle can be obtained, the carbon black can as a material used in other products.

Waste tyre disposal way

The main reason for the pyrolysis waste tyres are two techniques have been developed: First, pyrolysis process is more environmentally safe treatment than burning waste tyres; secondly, during pyrolysis processing, organic matter can transfer into a form of energy available with a good economy. Since pyrolysis tyres can achieve full recovery and reuse of valuable energy products with high economic and environmental benefits which stands represents the development direction of today’s waste tyres disposal.

Landfills/ deposits Currently the waste tyres processing in the world is still landfill or deposits, especially in some developing countries about 65% to 70%. This old method is not only take up lots of land area, but also can cause firs release toxic and hazardous gases, can easily become a breeding ground for mosquitoes brought epidemics and caused great harmful to the environment and human health.

Pyrolysis Waste tyre pyrolysis processing technology is adopt of a variety of industrial waste oil combustion heat generated fumes or electric heating devices, in the absence of oxygen or inert atmosphere pyrolysis the waste tyres, to get fuel oil with a high calorific value, rich in aromatics oil and valuable chemical products such as carbon black, which is a new way of processing the waste tyres. Pyrolysis includes three technology, oil technology, gasification and carbonization technology. In the pyrolysis reactor, the temperature is about 80 ~ 600 ℃ to pyrolysis process waste tyres to produce crude oil, and carbon black mixture. After further purified canning with liquefied petroleum gas, pickling mixture of oil, soda, after washing and white clay adsorption can be obtained by distillation of various petroleum products (such as solvent oil, aromatic oil, diesel, etc.); coarse charcoal after coarsely crushed black after magnetic separation and second grinding, magnetic separation and air separation step, various carbon black particle can be obtained, the carbon black can as a material used in other products.

Waste tyre disposal way

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications