Home>FAQ>Tyre/Plastic Oil to Diesel Distillation PlantWhat kind of waste plastic/tyre oil can be recycling by DOING oil distillation plant?

Home>FAQ>Tyre/Plastic Oil to Diesel Distillation PlantWhat kind of waste plastic/tyre oil can be recycling by DOING oil distillation plant?

What kind of waste plastic/tyre oil can be recycling by DOING oil distillation plant?

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

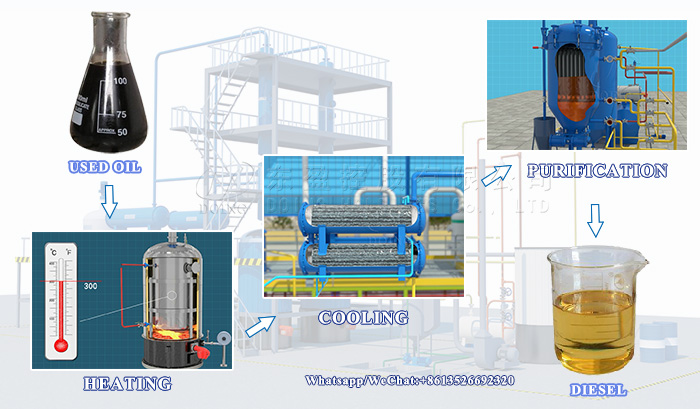

DOING waste plastic/tyre oil distillation plant can refine waste plastic/tyre oil into diesel through the steps of distillation, cooling, deodorization and decolorization. At the same time, it can also bring great profits by recycling waste plastic/tyre oils into diesel. So what kind of waste plastic/tyre oil can be recycling by DOING waste plastic/tyre oil refining plant?

Generally speaking, DOING waste plastic/tyre oil distillation plant can refine plastic pyrolysis oil, tire pyrolysis oil, waste crude oil, waste engine oil, waste lubricating oil, black heavy oil, etc. into diesel, and the diesel oil yield can reach 85%.

How to convert waste oil to diesel?

How to convert waste oil to diesel?

The specific working process of DOING waste plastic/tyre oil distillation plant is as follows:

1. Feeding and preheating: The waste plastic/tyre oil is sent to the distillation reactor through the oil pump, and the heat-conducting oil is heated to preheat the system. When the temperature of the distillation kettle reaches 290 degrees, the burner is turned on to heat the distillation reactor. The burner and the heat transfer oil are heated at the same time, which can speed up the distillation time and save fuel;

Waste plastic/tyre oil distillation process

Waste plastic/tyre oil distillation process

2. Condensation: When the temperature of the distillation reactor is between 380°C and 400°C, oil gas will be produced, and the oil gas will enter the horizontal condenser to be cooled into primary diesel oil and enter the oil tank; the original diesel oil has a darker color and an unpleasant smell. Deodorization and decolorization of raw diesel oil with catalyst and clay to obtain diesel oil;

3. Asphalt discharge: After refining, 10% asphalt will be obtained, and our vertical reactor can directly discharge the asphalt.

4. Exhaust gas: The non-condensable but combustible exhaust gas in the exhaust gas condensation process can be collected to heat the distillation reactor after being recycling by the exhaust gas purification system.

If you want to build up your own waste plastic/tyre oil refining project, or have other raw materials that you want to process, please feel free to consult DOING Company. Our engineers can provide you with suitable solutions, and customize the most cost-effective waste plastic/tyre oil refining plant.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications