Home>FAQ>Waste Tyre Recycling Pyrolysis PlantGeneral process flow of municipal solid waste pyrolysis plant

Home>FAQ>Waste Tyre Recycling Pyrolysis PlantGeneral process flow of municipal solid waste pyrolysis plant

General process flow of municipal solid waste pyrolysis plant

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

Here municipal solid waste mainly refers to solid waste waste tires and waste plastics. Municipal solid waste pyrolysis plant is also called MSW pyrolysis plant. We know that tires and plastics are composed of long molecular chains. After cracking, we can get fuel oil and carbon black from them. This is a promising project, and the equipment used is the municipal solid waste pyrolysis plant. The following is the general process flow of the municipal solid waste pyrolysis plant.

Municipal solid waste pyrolysis plant

Municipal solid waste pyrolysis plant

1. Feeding

Please look at the following picture. This is the feed door of the pyrolysis reactor, you can just put whole tires and plastic into reactor.

Feed door of municipal solid waste pyrolysis plant

Feed door of municipal solid waste pyrolysis plant

2. Heating

There is a heating system below the pyrolysis reactor. The reactor will rotate to make raw material evenly heated, and then the municipal solid waste will be pyrolyzed into oil gas under high temperature situation. Then oil gas will get out from the outlet and get into the condensers system through buffer chamber.

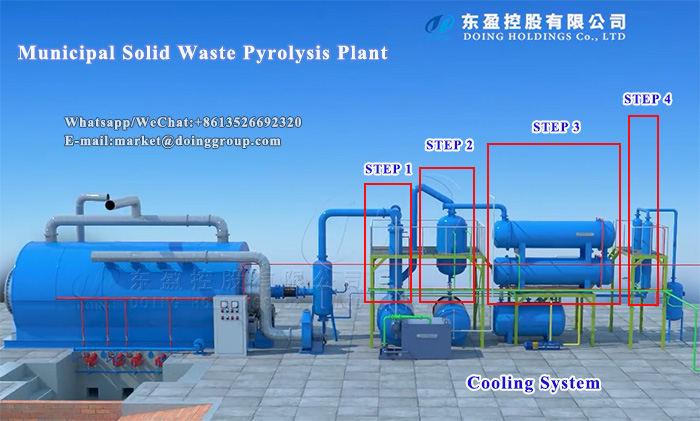

3. Cooling

The cooling system of municipal solid waste pyrolysis plant include 4 steps cooling with total 7 condensers. The first step cooling with two vertical condensers. The second step cooling with a water oil separator. The third step cooling with tow horizontal condensers, and last step cooling with two cooling tower.

4 steps cooling with total 7 condensers

4 steps cooling with total 7 condensers

There are total three oil tanks with this municipal solid waste pyrolysis plant, the cooled down liquid oil will be temporarily stored here. There is also some non-condensing gas which call tail gas, will be recycled to heating the pyrolysis reactor directly. You can see, our cooling system is very powerful. Because cooling system is very important. Good cooling system means good cooling effect and good cooling effect can guarantee high oil yield.

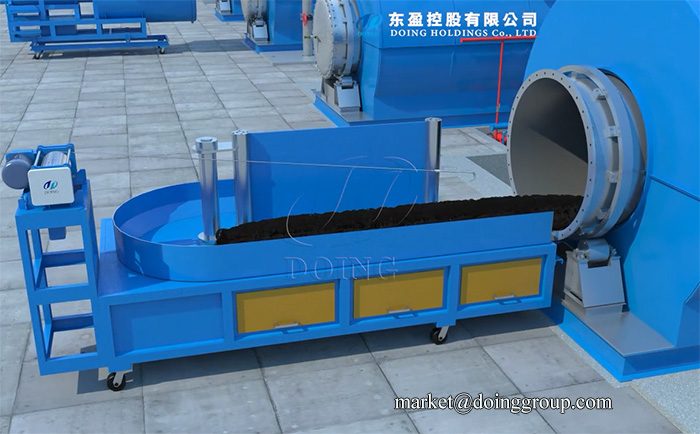

4. Discharging

After all the oil gas is collected, what remains in the municipal solid waste pyrolysis reactor is carbon black. We can use the carbon black screw conveyor to collect the carbon black. This slag discharge method is highly efficient and pollution-free which has welcomed by many customers. If your raw material are waste tyres, there are steel wire remains which need to be pulled from pyrolysis reactor.

Pull steel wire from pyrolysis reactor

Pull steel wire from pyrolysis reactor

This is the general process flow of municipal solid waste pyrolysis plant. There is no pollution in the whole process. Each link and component of municipal solid waste pyrolysis plant is carefully designed and practiced by DOING company. For more information about municipal solid waste pyrolysis plant, welcome to consult us directly.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications