Waste tyre pyrolysis to oil plant

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

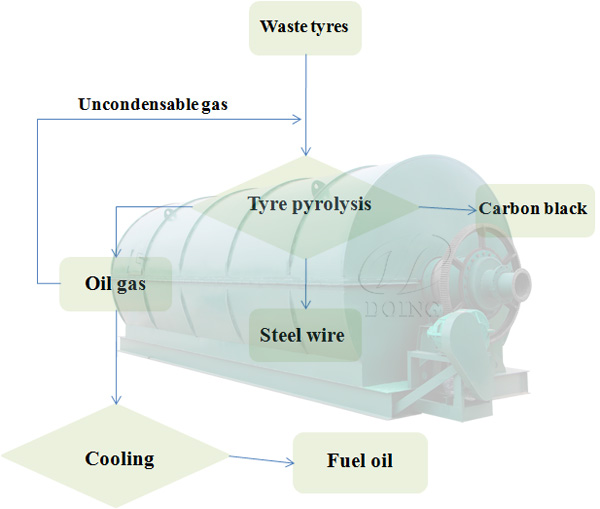

Waste tyre pyrolysis to oil plant has been proved to be a success in waste rubber tyre recycling. You can get fuel oil, carbon black and steel wire with this pyrolysis plant. Fuel oil can be substituted for industrial fuel materials and diesel (further refined). Therefore, Recycling of waste tyres can not only reduce “black pollution”, but also can create profits and relieve energy crisis. If you need, contact DOING company to get high quality waste tyre pyrolysis to oil plant for you.

DOING waste tyre pyrolysis to oil plant

DOING waste tyre pyrolysis to oil plant

Special technology of waste tyre pyrolysis to oil plant

1. DOING waste tyre pyrolysis to oil plant adopts advanced high temperature pyrolysis technology, and fundamentally eliminate the environmental and safety concerns.

2. With unique dispersion heating process waste tyre pyrolysis to oil plant can make the raw materials evenly heated. It not only makes high oil yield, but also ensures the good quality of oil and carbon black.

3. Combustible gas from production can be reused in heating system after purification. In addition, taking advantage of waste heat recycling technology, our machine can reach high thermal efficiency and reduce the production cost greatly.

4. Special flue gas purification system of waste tyre pyrolysis to oil plant can remove all pollutants in flue gas, such as H2S, CO, CO2, SO2, SO3, NOX, NH3 and other organic compounds and solid particles, so that the emission index has meet the high standards of Europe and America.

Special flue gas purification system

Special flue gas purification system

Waste tyre pyrolysis to oil plant technical parameters

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste tire | Waste tire | Waste tire |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 10 ton | 12 ton |

| 5 | Oil yield | 2.7-3.3ton | 4.5 -5.5ton | 4.8 -6.6ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 15KW | 15KW | 15KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

Main working process of waste tyre pyrolysis to oil plant

1. Put the waste tyres into the reactor and rotate the reactor clockwise, then seal the inlet door to ensure no gas leakage.

2. Heat the pyrolysis reactor slowly with heating materials. When the temperature reaches about 250 degrees, the waste tyre will be pyrolyzed and produce oil gas.

3. Oil gas from the reactor enters the condensing system, which is cooled down to liquid oil. Then collect liquid oil by the storage tank. Gases that cannot be liquefied under normal pressure will be recovered to the combustion system through a safety device. The gas can be used as fuel to heat the reactor.

4. After the liquid oil is collected, the reactor temperature will decrease. When the temperature drops to about 40 degrees, we can expel carbon black and steel wire.

Main working process of waste tyre pyrolysis to oil plant

Main working process of waste tyre pyrolysis to oil plant

Final products and their application

| Pyrolysis Oil |

|

1. can be sold directly. 2. Reprocessed into diesel and gasoline by waste oil distillation machine. 3. can be used as industrial fuel materials for burning. |

| Carbon Black |

|

1. can be sold directly. 2. Reprocessed into high quality carbon by the carbon black processing plant. 3. make carbon brick by briquetting machine. |

| Steel Wire |

|

can be reprocessed or used to make steel and iron rod. |

| Combustible Gas |

|

can be recycled as fuel to heat the reactor |

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications