Waste plastic pyrolysis machine

Waste plastic pyrolysis machine

Waste plastic pyrolysis machine

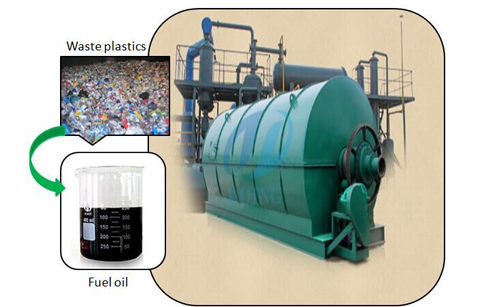

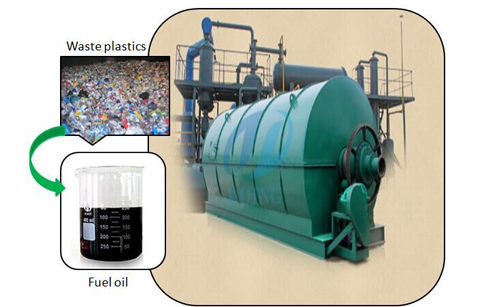

Waste plastic is a big problem for all countries, which not only cause pollution but also easily proliferate diseases thus endanger people’s life. Our waste plastic recycling machine is a green technology for waste plastic pyrolysis machine.

Waste plastic can dispose waste tires environmental friendly and bring considerable profit.

After processed by our waste plastic pyrolysis machine, you can get fuel oil. Fuel oil is a very good heating fuel. It has wide market in different countries.

Till now, our waste plastic pyrolysis machine has been exported to more than 30 countries, such as Italy, Romania, Turkey, Bangladesh, Nigeria, Malaysia, Mexico, Columbia, etc.

If there are many waste plastic thrown in your country, it will be a good chance for you to start the project of waste plastic recycling.

Welcome to contact us and get more useful information.

Waste plastic pyrolysis machine working processing

Waste plastic pyrolysis machine working processing

1.In the waste plastic pyrolysis process, the waste plastics will firstly be put into the reactor.

2.Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

3.Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

4.Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically.

5. Lastly, the released gas can achieve national emission standard through the dedusting system。

Waste plastic pyrolysis machine final product and application

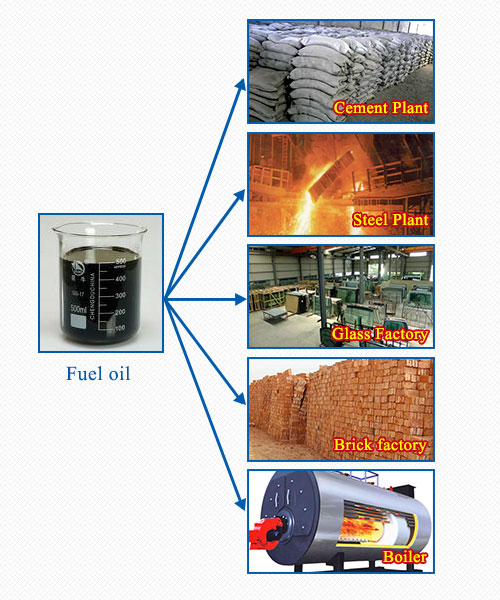

Plastic fuel oil: Oil from our waste plastic pyrolysis machine can be used as industrial fuel materials for burning.

Carbon black: Carbon black from this waste palstic pyrolysis machine is crude, so you can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. You can take carbon black for deep processing.

Waste plastic pyrolysis machine

Waste plastic can dispose waste tires environmental friendly and bring considerable profit.

After processed by our waste plastic pyrolysis machine, you can get fuel oil. Fuel oil is a very good heating fuel. It has wide market in different countries.

Till now, our waste plastic pyrolysis machine has been exported to more than 30 countries, such as Italy, Romania, Turkey, Bangladesh, Nigeria, Malaysia, Mexico, Columbia, etc.

If there are many waste plastic thrown in your country, it will be a good chance for you to start the project of waste plastic recycling.

Welcome to contact us and get more useful information.

Waste plastic pyrolysis machine working processing

Waste plastic pyrolysis machine working processing

2.Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

3.Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

4.Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically.

5. Lastly, the released gas can achieve national emission standard through the dedusting system。

Waste plastic pyrolysis machine final product and application

Plastic fuel oil: Oil from our waste plastic pyrolysis machine can be used as industrial fuel materials for burning.

Carbon black: Carbon black from this waste palstic pyrolysis machine is crude, so you can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. You can take carbon black for deep processing.