Waste tyre to oil recycling plant

Waste tyre to oil recycling plant

The waste tyre to oil recycling plant can convert waste tyre to oil(about 50%), carbon black(about 30%), steel wire(about 12%) and a little combustible gas(about 8%).

So, our Waste tyre to oil recycling plantbetter helps to solve two problems of waste tyres pollution and energy crisis.

Features of used tyre to oil recycling plant:

Features of Waste tyre to oil recycling plant

a> 100% Waste tyre to oil recycling plant is achieved.b> No chemical ingredients are used in process (environment friendly)

c> During and after the process; no soil, water or air pollution is observed.

d> Creates economically valuable products out of wastage tyres (These are an industrial product that have a good market value and demand)

e> The most cost-effective wastage tyre recycling technology in the world.

f> Raw material (wastage tyre) is cheap and easy to provide. These are the by-products of tyre production.

g> Each recycled ton of tyres preserves 10 tons of CO2 that is a major green house gas.

h> The process can be applied to all rubber based materials.

i> The system creates an alternate source of energy to replace petroleum products and natural gas.

j> System gives the opportunity to governments and local administrations to deal with the wastage tyre problem to a great extent.

k> The process of Pyrolysis has duration of 8 to 16 hours, depending on the quantity and size of tyre (car tyre, truck tyre, etc.). During the process different vacuum values are applied in pre-determined temperatures and in different phases. Different gases are obtained and the condensed gas is stored as a fuel-oil in tanks.

Waste tyre to oil recycling plant

| Item. | Features |

| Catalyst Room | One Big Catalyst room, in this way, can speed up the process of pyrolysis. |

| Horizontal Condensor | Two horizontal condenser, the cooling area of one horizontal condenser can be 50sqm. 100sqm totally.In this way, the oil output will be guaranteed. |

| Anti back devices | Two anti back fire devices, it is our second water seal, and also reuse the exhaust gas as burning material, two anti back fire device, more safety, more energy saving. |

The Perfect Solution (Pyrolysis Process):

Pyrolysis is the decomposition of organic compounds under oxygen free (anaerobic) atmosphere that produces gas, oil, carbon black and steel. Efficient industrial Pyrolysis is a process to treat the rubber and industrial plastic wastage as well.

As a result of pyrolysis of wastage tyres one obtains,

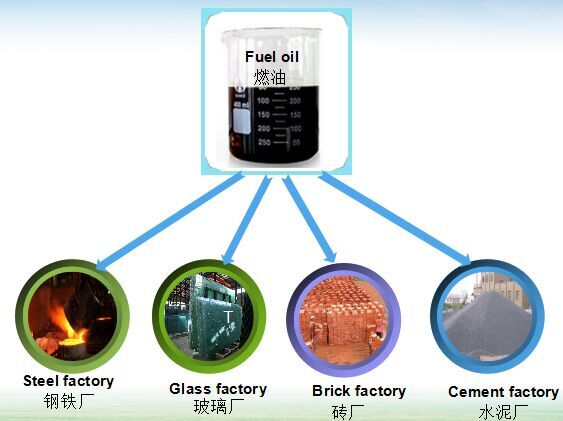

FUEL OIL (45% to 50%)

Fuel oil application

CARBON BLACK (30% to 35%)

Carbon black application

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

a> Electric cable jacketing

b> Conveyor band

c> Carrier Bands

d> Hose and doormat

e> Black nylon bag, Plastic pipes

f> Rubber additive

g> Automotive spare parts

h> Black colorant in rubber materials

i> Industrial rubber products

j> Fire fighting

STEEL WIRE (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after the Pyrolysis recycling process is completed. Valuable steel wires are pressed and sold to steel and scrap dealers.

GAS (5% to 8%)

Non-Condensable gases arise during the pyrolysis process. There are some advantages such as

a> It has higher calorific value as compared to natural gas.

b> It can be replaced where natural gas and propane are stored.

c> The high energy gas may be utilized as a source of energy for the Pyrolysis process.

d> The amount of gas generated in the system is 5% to 8% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 500 - 800 day gas, which has an enormous energy potential when evaluated.