Recycling plastic bags to oil machine

Recycling plastic bags to oil machine

Recycling plastic bags to oil machine

Recycling plastic bags to oil machine working process

Recycling plastic bags to oil machine

Reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃ (250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied into oil and stored in the oil tank. The incondensable gas through dusulphuration and dedusting by hydroseal will be led to the furnace for recycling.

After all the above work has been done, cool down the reactor. Then the carbon black will be discharged automatically.

There possibly will be a little exhaust gas left, and you should not expel it until it has reached the emission standard.

Before starting next batch, make sure all the work has been done.

We will get plastic oil and carbon black by Recycling plastic bags to oil machine

Plastic oil application

45% plastic oil

1. Add it into heavy oil generator to produce electricity.

2. Used as heating material.

3. Sell it into oil refining factory to further process it.

Sale market :Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc.

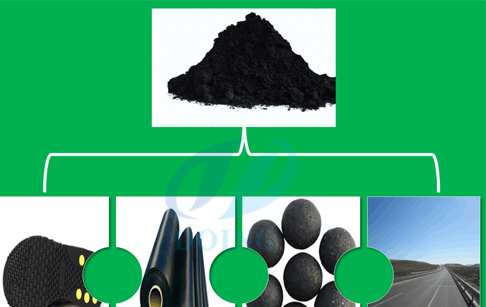

30% Carbon black

Carbon black application

2. Further process it into color master batch as basic material to make pipes, cable jacket…etc. Carbon black applicatio to Coal briquette factory, plastic factory, cable factory, etc.

10% Waste gas Recycled into fire furnace to heat react

As an industry-leading pyrolysis plant manufacturer, the above-mentioned recycling of plastic bags to oil machines is the preferred equipment for most customers interested in this project. Of course, we have a more advanced set of equipment for recycling plastic bags to oil machines.

Another recycling plastic bags to oil machine in our company

3 tyres oil can be obtained by the machine

Prev: Tyre recycling machinery for sale

Next: The end!