Plastic to oil recycling machine

Nowadays, with human exploiting and environment degradation, natural energy especially oil energy is becoming less and less, on the contrary, municipal solid wastes are becoming more and more. DOING company can not produce natural energy, but we can turn the normal daily wastes like tyres and plastics into oil energy, which can be used as fuel in many industrial fields. DOING is specialized in manufacturing waste plastic to oil recycling machine, waste tire/plastic oil distillation machine and used engine oil refining machine, decoloring and bad smelling removing machine, you can get diesel as final products.

Waste plastic to oil recycling machine

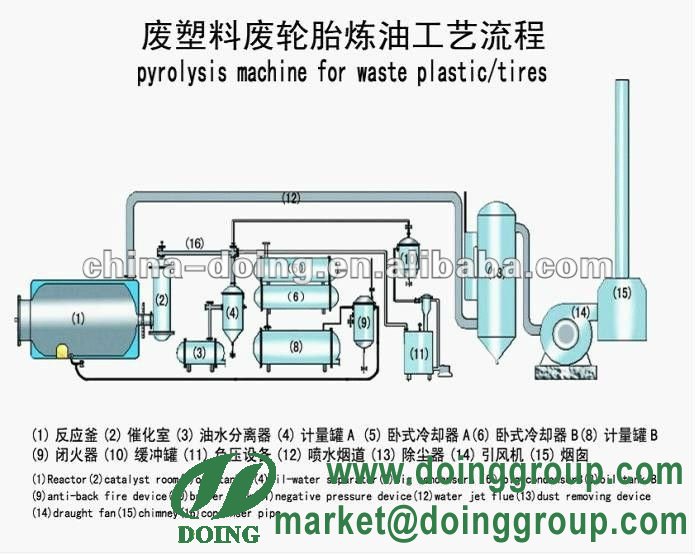

1. Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 300 degree Celsius, waste plastic will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

Last, when the temperature falls to 100 degree Celsius, worker could put steel wire hook to reactor to take steel wire out. After all these steps, you can start another batch.

Plastic to oil recycling flow chart