Waste plastic tyre pyrolysis plant

Waste plastic tyre pyrolysis plant

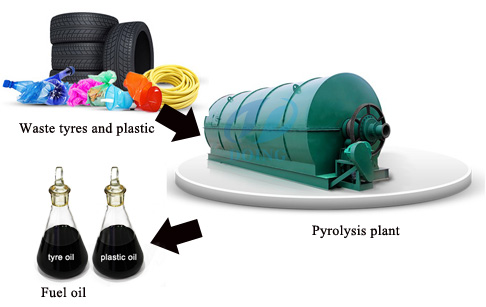

Waste plastic tyre pyrolysis plant is a set of plant that can extract oil, carbon black and steel from waste tires. The oil from it can be detached to gasoline and diesel for fuel. With the large quantity of waste tire in the world annually and the increasing international oil price, waste tire refining is becoming one of the most promising industry.

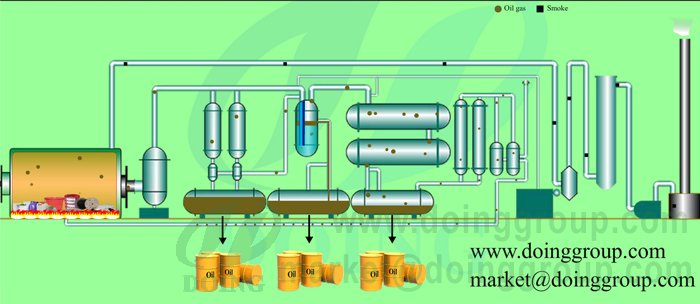

Waste plastic tyre pyrolysis plant working process

Waste plastic tyre pyrolysis plant working process

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

Last, when the temperature falls to 100 degree Celsius, worker could put steel wire hook to reactor to take steel wire out. After all these steps, you can start another batch.

Waste plastic tyre pyrolysis plant final product and application

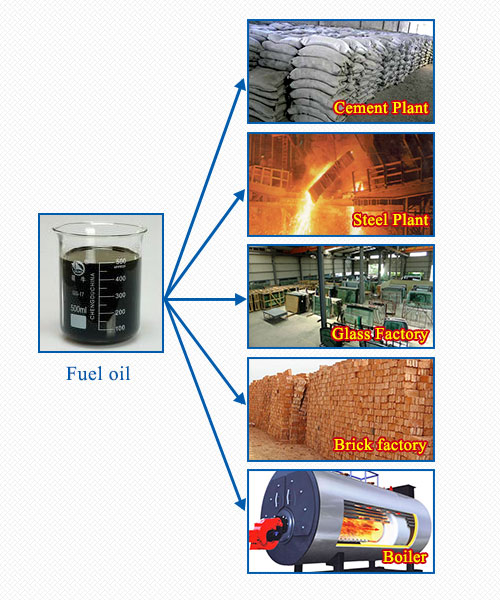

Fuel oil application

The main application of oil products produced by our waste plastic tyre pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

2.Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

3.Steel Wire (10% to 15%)

The third product of waste tyre oil extraction machine is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

4.Carbon Black Powder (30% to 35%)

Carbon black application