Small capacity waste tyre recycling pyrolysis plant

Every year a large amount of tyre waste is discarded in the Earth. These plastic to with stand the natural process of decomposition of all. According to statistical analysis , Waste tyres generated more than 250 million tons each year. A lot of these tyres garbage is used to fill the land , which in turn may result in a waste land to create a major threat to the environment in the future. People use and dump waste tyres almost every day.

The right way to disposal waste plastic and tyre

Waste tyre recycling pyrolysis plant can pyrolysis down of waste tyres and plastic to energy. Waste tyre recycling pyrolysis plant is an industry conducted pyrolysis . In the Waste tyre recycling pyrolysis plant , the long- chain polymers break down into smaller chains of hydrocarbon gases and pyrolysis oils. Heat required for the catalytic reaction .

Waste tyre recycling pyrolysis plant

In pyrolysis as a process, the polymer waste is not burned, instead it is broken down into usable finished products like Pyrolysis Oil, Hydrocarbon Gas and carbon. In case of plastic / tyre waste management, pyrolysis is better alternative compared to incineration or dumping. Incineration is burning of waste which leads to loss of valuable energy from polymer waste. Dumping of polymer waste is known to cause land pollution. By pyrolysis of polymer waste, it is possible to recover value from waste in the form of Pyrolysis oil, Hydrocarbon gas and charcoal.

Waste tyre Solution: waste tyre recycling pyrolysis plant:

Usage: Waste tyres Recycling to Fuel Oil

Input: small tyres, rubbers,soles etc.

Output: 45%-52% fuel oil, 30%-35% carbon black , 5%-8% gas.

Heating material: coal/wood/fuel oil/natural gas

Machine cover area: usually 400 square meters.

Reactor material: Q245R Boiler plate.

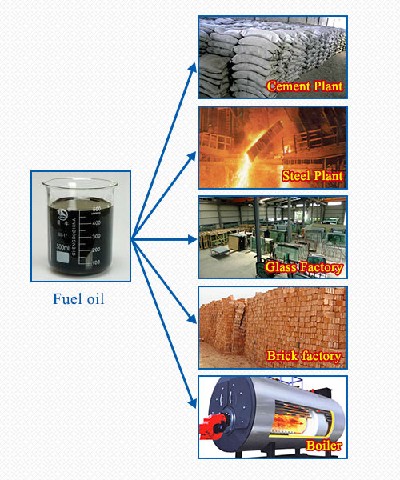

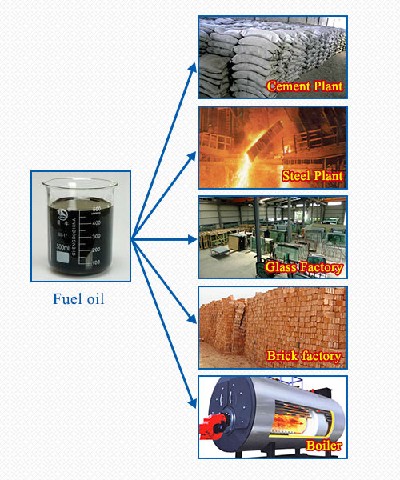

Fuel oil usage

Fuel oil can be used as heating material to heavy industries, like cement factory, brick factory, glass making factory, boiler etc.

Fuel oil usage

The right way to disposal waste plastic and tyre

Waste tyre recycling pyrolysis plant can pyrolysis down of waste tyres and plastic to energy. Waste tyre recycling pyrolysis plant is an industry conducted pyrolysis . In the Waste tyre recycling pyrolysis plant , the long- chain polymers break down into smaller chains of hydrocarbon gases and pyrolysis oils. Heat required for the catalytic reaction .

Waste tyre recycling pyrolysis plant

In pyrolysis as a process, the polymer waste is not burned, instead it is broken down into usable finished products like Pyrolysis Oil, Hydrocarbon Gas and carbon. In case of plastic / tyre waste management, pyrolysis is better alternative compared to incineration or dumping. Incineration is burning of waste which leads to loss of valuable energy from polymer waste. Dumping of polymer waste is known to cause land pollution. By pyrolysis of polymer waste, it is possible to recover value from waste in the form of Pyrolysis oil, Hydrocarbon gas and charcoal.

Waste tyre Solution: waste tyre recycling pyrolysis plant:

Usage: Waste tyres Recycling to Fuel Oil

Input: small tyres, rubbers,soles etc.

Output: 45%-52% fuel oil, 30%-35% carbon black , 5%-8% gas.

Heating material: coal/wood/fuel oil/natural gas

Machine cover area: usually 400 square meters.

Reactor material: Q245R Boiler plate.

Fuel oil usage

Fuel oil can be used as heating material to heavy industries, like cement factory, brick factory, glass making factory, boiler etc.

Fuel oil usage