Plastic waste recycling process pyrolysis plant

Plastic waste recycling process pyrolysis plant

Plastic waste recycling process pyrolysis plant can convert waste plastic to fuel oil ,carbon black。

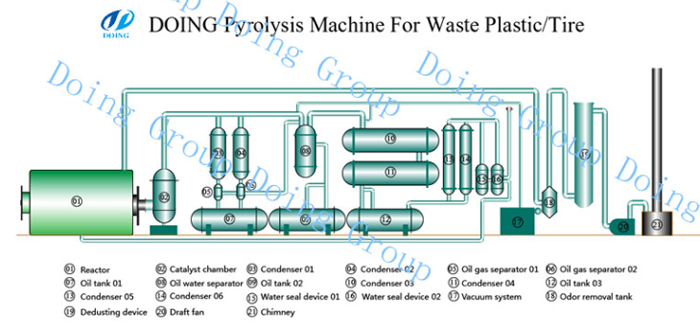

Plastic waste recycling process pyrolysis plant working process

Plastic waste recycling process pyrolysis plant working process

→ The constant temperature heating system supplies heat to the pyrolysis reactor. The raw materials are continuously fed into the pyrolysis reactor and spreaded by the system, completing pyrolysis reaction with the high-efficiency catalyst.

→ The pyrolyst oil gas is turned into high quality fuel oil and small amount of combustible gas after following processes such as fractional distillation separation, fixed bed secondary gas catalyzing and de-waxing etc.

→ The combustible gas is totally used as fuel to the system after scrubbing, which achieves heat energy self-supporting. The gas after being burnt will be qualified discharged after gas purification process.

→ The small amount of solid residue generated from the reaction is continuously discharged out of the reactor, and that could be further processed into fuel

Fuel Oil (45% to 52%)

Fuel oil application

The main application of oil products produced by Plastic waste recycling process pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tyres can be carried with licensed tanker trucks.

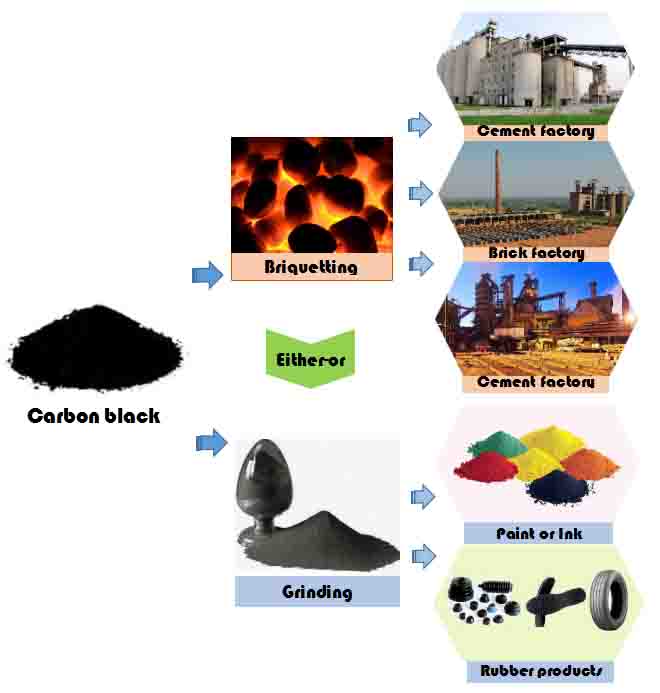

Carbon Black (30% )

Carbon Black (30% )

Carbon black application

The second product of Plastic waste recycling process pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.