Fully continuous waste tyre pyrolysis plant

Fully continuous waste tyre pyrolysis plant

Fully continuous waste tyre pyrolysis plant raw material

The raw material of fully continuous waste tyre pyrolysis plant

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

Fully continuous waste tyre pyrolysis plant feature

The feature of fully continuos waste tyre pyrolysis plant

2.PLC operation, saving manpower.

3.Feeding in every second and minute,Automatic ejiecting wastes residue,Fuel product day and night

4.Durable ,prolong life

Fully continuous waste tyre pyrolysis plant final product application

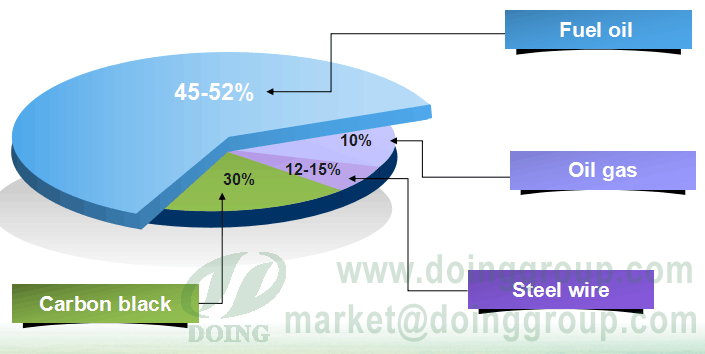

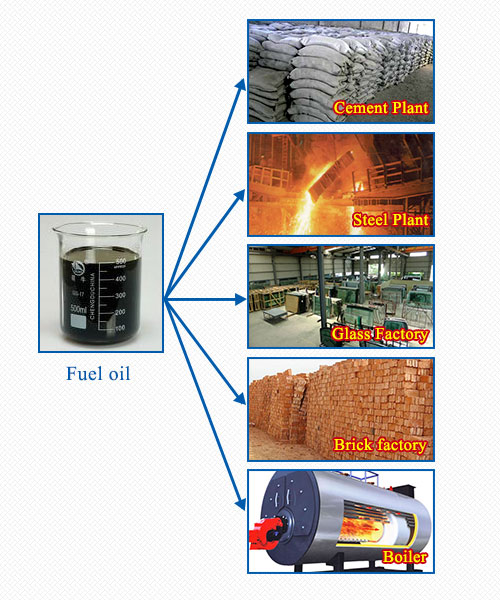

Fuel Oil (45% to 52%)

The main application of oil products produced by Doing fully continuous waste tyre pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tires can be carried with licensed tanker trucks.

Steel Wire (12% to 15%)

The third product of fully continuous waste tyre pyrolysis plant is steel wire, the quantity of steel wire is about 12% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black Powder (30%)

The second product of fully continuous waste tyre pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Gases (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.