Continuous pyrolysis tire to fuel machine

Continuous pyrolysis tire to fuel machine

For our continuous pyrolysis tire to fuel machine, the applicable raw materials can be any kinds of waste tires, such as bicycle tires, motorcycle tires, car tires, truck tires, OTR tires, etc.

Continuous pyrolysis tire to fuel machine raw material

Excpet the steel wire extracted out from waste tires in the first stage pretreatment process, the final products from continuous pyrolysis tire to fuel machine process will be fuel oil and carbon black.

Continuous pyrolysis tire to fuel machine advantage

DOING 3D continuous pyrolysis plant

1: Fully automatic with low labour cost

Continuous pyrolysis tire to fuel machine is controlled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2:Fully pyrolysis for high oil output

Our Continuous pyrolysis tire to fuel machine adapts to multiple reactor design which can make fully pyrolysis of waste plastics, thus to get high oil output.

3:Big capacity

Also due to continuous feeding and discharge system, and unique multiple reactor design, our fully automatic continuous waste plastics pyrolysis plant can process at least 10 tons waste plastics per day, up to 100T/D.

4: Internal rotating for continuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve he real sense of continuous process. But our Continuous pyrolysis tire to fuel machine reactor adapts internal rotating method, which no need to worry about the sealing of the external rotating system.Continuous working save time and energy

5:Long working life

During the continuous pyrolysis tire to fuel machineprocess, reactor is heated by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors.

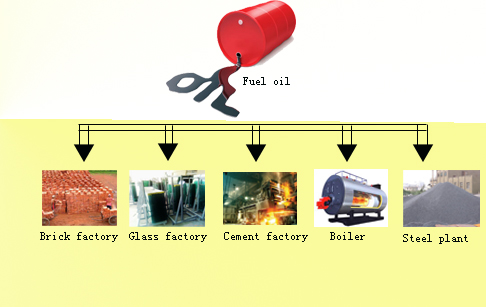

Fuel oil application

1. Add it into heavy oil generator to produce electricity.

2. Used as heating material.

3. Sell it into oil refining factory to further process it. Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc.

Carbon black application(30-35%)

2. Used as heating material.

3. Sell it into oil refining factory to further process it. Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc.

Carbon black application(30-35%)

Carbon black application

The carbon black of continuous pyrolysis tire to fuel machine can be used as heat source to heat the Reactor, it even has a little higher heating value than coal. We can further process carbon black into pellets as a heating fuel instead of coal. Our customers use the carbon black pellets to heat pyrolysis plant or sell to cement factories, steel factories, glass factory, brick factory and so on.