Home>News>Company NewsIs it costly to invest in an environmentally friendly tyre pyrolysis plant,how about the profits?

Home>News>Company NewsIs it costly to invest in an environmentally friendly tyre pyrolysis plant,how about the profits?

Is it costly to invest in an environmentally friendly tyre pyrolysis plant,how about the profits?

Company News / Chat online / Give me a price / September 20, 2018

Waste tyre

With the gradual improvement of people's living standards and the rapid development of the logistics industry, the number of private cars and the number of trucks in China have increased year by year. The increase in the number of vehicles has led to economic development, while the consumption and wear of automobile tires has also produced a lot of garbage - used tires. A few years ago, used tires were thrown away as garbage, which greatly polluted the environment we lived on. At this time a new industry is quietly emerging, this is - recycling of used tires. It mainly uses high temperature pyrolysis chemical reaction to crack waste tire into fuel oil, carbon black, steel wire and combustible gas.

DOING company waste tyre disposal pyrolysis plant

At present, with the severe environmental problems, people have begun to pay attention to the waste tire recycling industry. Although there are many waste tire recycling equipment on the market, not every supplier's equipment is environmentally friendly. DOING company's waste tire cracking equipment adopts strict EU pollution control standards, and all emissions can reach local environmental protection. The standard of the department. The waste tire refining equipment produced by DOING company attaches great importance to its own environmental protection system, which is mainly reflected in the following four aspects:

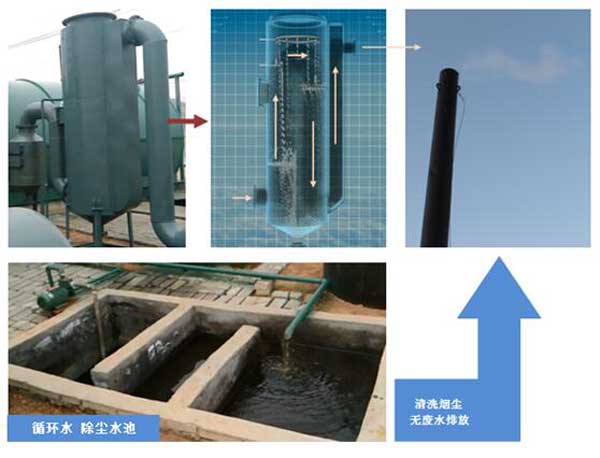

First, water treatment:

Part of it is the condenser water, no pollution.

The other part is dust removal water, which is circulating water, only evaporation, no emissions.

Second, waste gas treatment:

Environmental pretection system

First, when feeding, a small amount of water vapor and a small amount of oil and gas are leaked from the feed port, which is recovered by the hood and sent to the dust collector by secondary combustion.

Second, when burning coal, the soot is pumped by the induced draft fan to the dust collector for discharge from the chimney to ensure that the soot emissions meet the relevant standards.

Thirdly, the non-recoverable natural gas under the normal temperature and normal pressure below C4 from the reaction kettle is sent to the furnace through the gas burner through the closed firearm, which is energy-saving and environmentally friendly. In the production process, the equipment is operated in a fully sealed state, and the phosphating solution has no odor.

Third, the waste residue treatment:

First, the waste residue discharged from the reaction vessel is non-toxic and odorless at high temperature, and can be used for working carbon black or for building materials.

Second, there is residual slag in the burning coal, which can be used for building materials, and the two emit zero.

Fourth. Noise treatment:

The tyre pyrolysis plant uses low-noise fan, the noise is less than 60 decibels, and the noise of the power part and the noise of the feeder are not more than 50 decibels.

10 sets tyre pyrolysis plant installed in Mexico

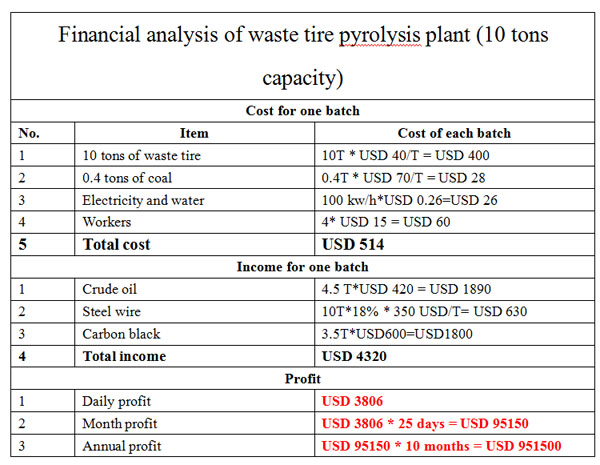

Mexico one set 10T waste tyre disposal pyrolysis plant profit analysis

From this table we can easily find out that our Mexico customer one day can earn 3806 USD X 10 = 38060USD with his 10 sets 10T/D tyre pyrolysis plant!!!

This number looks really tempting, and we have to tell you another good news. Just in this year, our team of R&D engineers has developed a wind conveying carbon black discharge system. This system has the following advantages over the previous conventional carbon black conveyer:

2 types carbon black discharge system comparison

1. Save time for drying and slagging

2. Saving floor space

3. The carbon black emission is relatively concentrated, which is convenient for post-package transportation.

Not only that, but the biggest design highlight is the size of the tyre pyrolysis plant. The larger tyre pyrolysis plant scale, the more obvious the advantages of the system, the more money it can help you save. For example, the customer in Mexico, because of the size of his tyre pyrolysis plant, the customer is using our wind conveying carbon black discharge system.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications