Are Waste Plastic and Waste Tyres Really Waste?

Are Waste Plastic and Waste Tyre Really Waste?You are wrong if you thought like this.Cos, there have many waste tyre and waste plastic generated every year, so, recycled waste tyre and waste plastic is a good chance to invest.So, How we can use waste tyre and waste plastic?

Henan DOING Mechanical Equipment Co., Ltd is professional in producing waste tyre and waste plastic to oil machine. This pyrolysis machine can convert waste plastic and waste tyre into fuel oil, carbon black and steel wire. You can sell a good price in the local market. The pyrolysis machine is your best choice with save energy, small invest and return back quickly.

Waste tyre/ plastic to oil machine

DOING pyrolysis machine has 5 advantages as below:

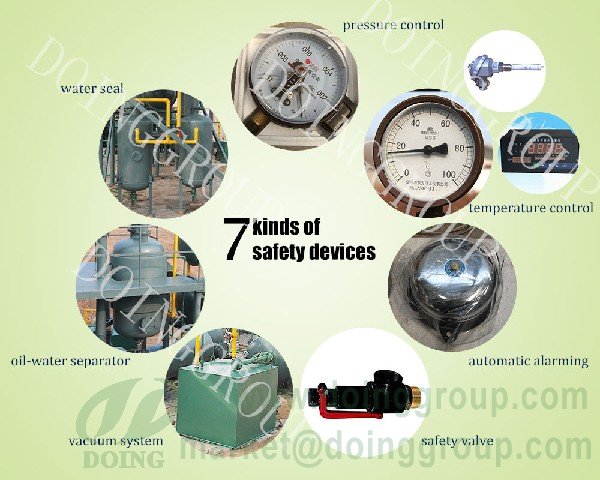

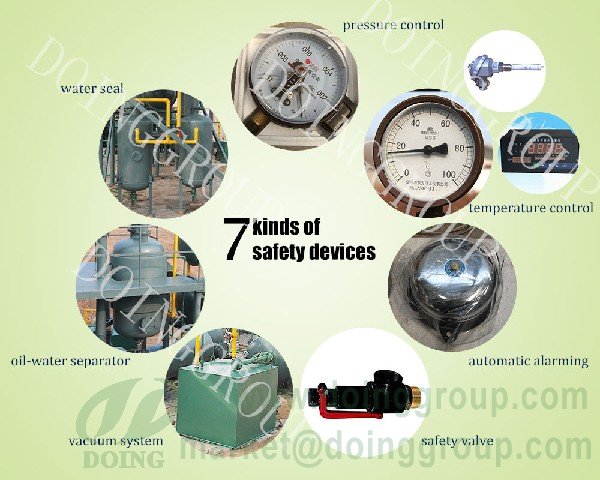

Safety:

1. Auto welding to improve working efficient, ensure machine quality, avoid accident.

2. Special design to avoid the jam with X-ray test, ensure safety running.

3. Vacuum system ensures the whole line working well.

Pyrolysis machine with safety devices

Environmental protection:

1. Dust and sulfur removal system remove smoke and sulfur.

2. The exhaust gas (include methane to butane) will be directly recycled to furnace for fuel, no gas pollution.

Pyrolysis machine with environmental protection device

High oil yield:

1. Three cooling processes ensure the oil gas liquefied sufficiently.

2. Catalyst chamber ensure the raw material pyrolysis totally.

Pyrolysis machine with cooling device

Long service life:

1. Special boiler plate:Q245R with 16mm thickness.

2. Auto welding to ensure the machine life, service life will be 8-10years.

High quality steel plate

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

Energy saving-tail gas recycling system

Good After-sale service:

1. Oversea guide installation and training customers’ worker and try running.

2. 1 year warranty.

Pyrolysis machine project all over the world

Henan DOING Mechanical Equipment Co., Ltd is professional in producing waste tyre and waste plastic to oil machine. This pyrolysis machine can convert waste plastic and waste tyre into fuel oil, carbon black and steel wire. You can sell a good price in the local market. The pyrolysis machine is your best choice with save energy, small invest and return back quickly.

Waste tyre/ plastic to oil machine

Safety:

1. Auto welding to improve working efficient, ensure machine quality, avoid accident.

2. Special design to avoid the jam with X-ray test, ensure safety running.

3. Vacuum system ensures the whole line working well.

Pyrolysis machine with safety devices

Environmental protection:

1. Dust and sulfur removal system remove smoke and sulfur.

2. The exhaust gas (include methane to butane) will be directly recycled to furnace for fuel, no gas pollution.

Pyrolysis machine with environmental protection device

1. Three cooling processes ensure the oil gas liquefied sufficiently.

2. Catalyst chamber ensure the raw material pyrolysis totally.

Pyrolysis machine with cooling device

1. Special boiler plate:Q245R with 16mm thickness.

2. Auto welding to ensure the machine life, service life will be 8-10years.

High quality steel plate

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

Energy saving-tail gas recycling system

1. Oversea guide installation and training customers’ worker and try running.

2. 1 year warranty.

Pyrolysis machine project all over the world