Home>FAQ>Tyre/Plastic Oil to Diesel Distillation PlantWhat is waste oil recycling plant? How does it work?

Home>FAQ>Tyre/Plastic Oil to Diesel Distillation PlantWhat is waste oil recycling plant? How does it work?

What is waste oil recycling plant? How does it work?

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

Waste oil recycling plant is also called waste oil distillation machine, which can recycle waste oil, crude oil, black oil, pyrolysis oil, etc. to diesel, using in heavy oil machinery, ships, trucks, boiler heating, generator and so on. In the past 13 years, DOING has continuously developed and improved its process, resulting in the researching of the best waste oil recycling plant, adopting the latest technology and best designs and materials.

Then I would like to talk about how waste oil recycling plants work:

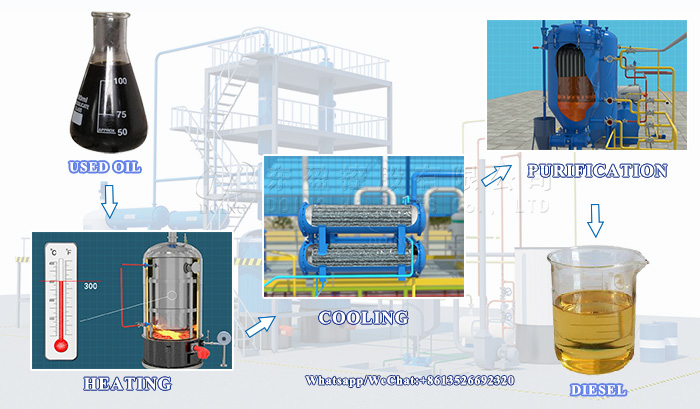

Brief working process of DOING waste oil recycling plant

Brief working process of DOING waste oil recycling plant

The DOING waste oil recycling plant process is divided into several steps: dehydration, refining, decolorization and deodorization, further decolorization and filtration.

1. Dehydration process

Through DOING vertical distillation reactor dual heating system to realize dehydration, separating most of the water. Continuous heating to remove the water in the waste oil, while the low boiling point of the broken chain of low carbon matter is steamed.

2. Distillation process

DOING waste oil recycling plant has two different designs, using different forms of catalysts.

1) The common waste oil recycling plant: This design adopts liquid catalysts(acid and alkali), using conventional liquid chemicals to precipitate impurities and separate them. After heating, the waste oil will be distillated to oil gas; after going through the cooling system, we can obtain liquid oil, then add the liquid catalysts. Finally, we can get the diesel.

Two types of DOING waste oil recycling plants

Two types of DOING waste oil recycling plants

2)The new design waste oil recycling plant: This design adopts solid catalyst(specially researched and equipped by DOING engineers) to settle impurities and purify the oil. The Solid catalyst tower is connected with the horizontal condensers, so when the oil gas goes through the catalyst tower and cooling system, we can get the diesel directly, which is more convenient and efficient.

3. Decolorization and deodorization process

After the liquid catalyst or solid catalyst treatment, the oil will be sent to the next decolorization process. In this way, the color of the diesel will be improved, and the odor in it will be eliminated.

4. Further decolorization and filtration process

Further decolorization and filtration process is to use active clay adsorption to remove untreated asphalt, gum, cycloalkanes, polycyclic aromatic hydrocarbons and other impurities to play a role in further decolorization filtration. After this treatment, the obtained oil has been completely diesel with good quality and clear color.

Project cases of DOING waste oil recycling plant

Project cases of DOING waste oil recycling plant

At present, DOING waste oil recycling plant has cooperated with many customers and some waste oil recycling plants have been running successfully, such as in Indonesia, Mexico, Malaysia, etc. So if you want to know more about our waste oil recycling plant, or want to carry out similar projects, please feel free to contact the DOING’s business managers. We will match the appropriate configuration and solution according to your needs.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications