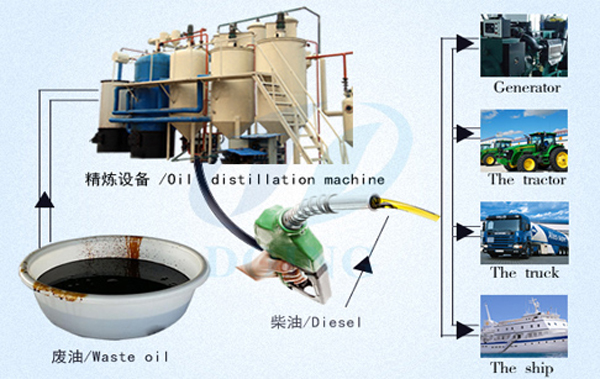

How to change used oil to diesel fuel ?

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

Used oil

Waste tire to diesel oil plants

DOING company used oil to diesel plant

How to change used oil to diesel fuel ?

Used oil to diesel fuel machine working process

1. Pump raw material into distillation reactor by oil pump. Then close the feeding inlet to totally sealed. (Continuous plant adopts automatic feeding device);

2. Use coal/wood/natural gas/fuel oil/electricity to heat the reactor, and the liquid oil will slowly become oil gas, which will be liquefied into fuel oil by the cooling pipe and condensers and then go into oil tank. For getting higher quality diesel, you are required to control the temperature over 150 Celsius degrees. When the temperature decreases to below 150 Celsius degrees, the gasoline will be cooled out;

3. Some gases like Methane, Ethane, Propane, Butane cannot be liquefied will be recycled into the furnace for heating the reactor;

4. It will produce some smoke when fuel materials are burnt. The smoke will be processed by dedusting system completely;

5. The exhaust gas will go into the chimney sucked by draft fan, before emission the exhaust gas will become steam, no pollution.

And at present we have cooperation with many used oil to diesel fuel machine factory at home and abroad, they have high evaluation of our used oil to diesel fuel machine:

Doing used oil to diesel fuel machine

Cost. The price of re-refined oil is comparable to that of virgin oil. In some cases, it costs less.

Performance. Tests after the test showed that the refined non-standard diesel oil has the same performance as the national standard diesel.

Who is using it? Non-standard diesel fuel obtained by used oil to diesel fuel machine can be used for heavy machinery, generators, and boilers. Through feedback from customers, the refined diesel can reach the standard of No. 6 diesel at the local gas station and is directly used for the diesel supply at the immediate gas station.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications