Home>FAQ>Tyre/Plastic Oil to Diesel Distillation PlantHow does the fractional distillation of crude oil work?

Home>FAQ>Tyre/Plastic Oil to Diesel Distillation PlantHow does the fractional distillation of crude oil work?

How does the fractional distillation of crude oil work?

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

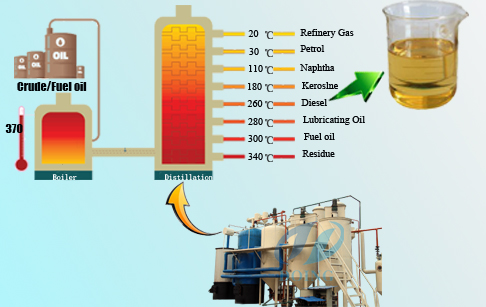

Fractional distillation of crude oil machine

Crude oil fractionation is mainly the use of high-temperature distillation and condensation chemistry. The process of separating the moisture and other impurities from the sand inside the fuel to obtain clean and transparent non-standard diesel.

How does the fractional distillation of crude oil work?

Fractional distillation of crude oil working process

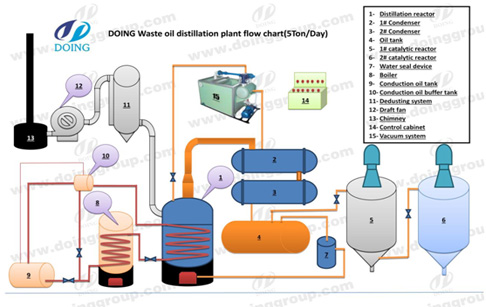

2. Distilled oil and gas enter the condensing system and is then liquefied into light oil and falls into the tank.

3. After the deodorizing and deodorizing treatment of the obtained light oil, the final result is a clean, transparent, odorless and tasteless diesel fuel.

4. Finally remove the bitumen produced during the distillation.

Fractional distillation of crude oil final products

In addition, the DoingGroup's fractional distillation of crude oil equipment also has two alternative systems:

Rapid heating system:

The rapid heating system of the refining equipment uses the circulating medium to heat the fuel at the same time. On the one hand, it can save fuel, and on the other hand, it can speed up the distillation speed.

Diesel purification system:

The diesel refined from the standard refining system is brownish yellow. If you want to get better color diesel, we can also provide a deep purification system, and finally you can get pale yellow diesel products.

The two alternative systems, on the one hand, ensure that the crude oil can be fully distilled out of oil and gas, and on the other, it can ensure that the distillate oil gas liquefied into light oil is filtered. If you have the intention of investing in fractional distillation of crude oil equipment, please contact DoingGroup. We will provide you with the most professional equipment and equipment to guide the installation!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications