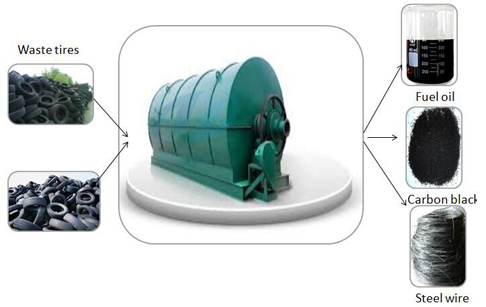

Waste tyre oil extraction machine

Doing Group as a leading oil extraction machine manufacture, we need to develop all the time. According to the customers’ requirement, we design a new waste tire to fuel oil waste tyre extraction machine with lower cost and higher oil output. it make the pyrolysis oil become easy.Waste tyre oil extraction machien is a new pyrolysis technoloty can extraction oil from waste tyre.

Waste tyre oil extraction machine

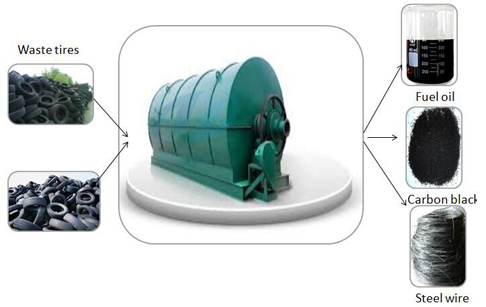

Used tyres can be turned into black gold or more precisely into a quality diesel fuel with a new tyre recycling technology.Waste tyres are intractable waste and cause considerable concern for the environment not only in the storage requirements of used tyres a year. They are also an inherent fire danger and can result in the release of toxic gases into the atmosphere. This intractable waste adds greater pressure on the current land filling policy of many councils.

The technology can be used to rid this waste in an environmentally-friendly manner. There are no toxic gases produced and the final products of diesel, carbon black and steel are reusable in many ways.

As there is no molecular change in the manufacture of tyres, the catalytic process is now available to waste tyre oil extraction machine can convert waste tyre to fuel oil , carbon and steel products. It can restore the waste rubber to its original components.

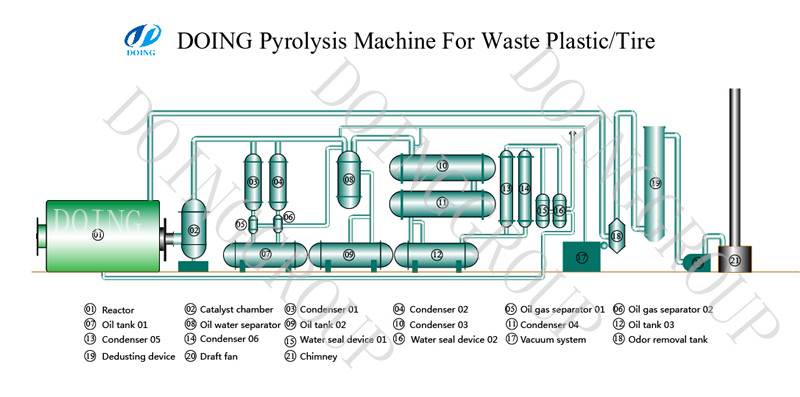

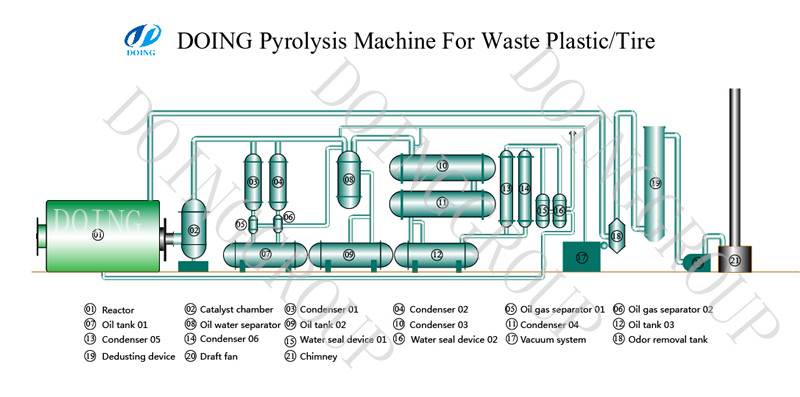

Flow chart of Waste tyre oil extraction machine

Waste tyre oil extraction machine flow chart

Waste tyre oil extraction machine advantage

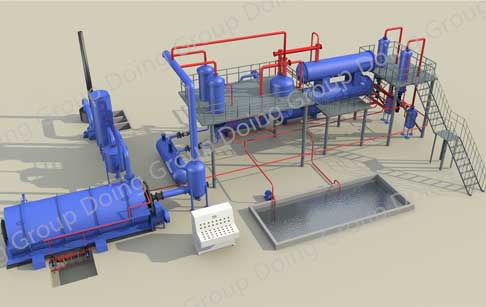

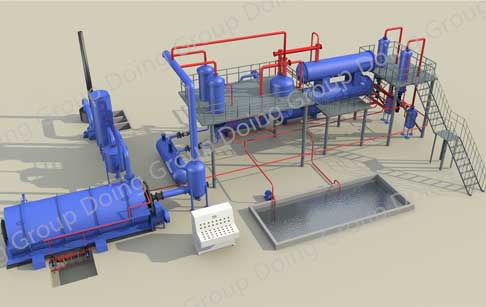

Waste tyre oil extraction machine 3 D picture

1. Safe. The waste tyre oil is equipped with mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee 100% safety in the pyrolysis process.

2. Energy-saving. By the extra gas recycling system, the gas that can not be condensed will be recycled to the burning room. It can replace the fuel material to heat the reactor, which will reduce additional fuel consumption.

3. Environment friendly. In the dedusting system, three steps (water spray, ceramic ring filter, washing chamber) are used to dedust the extra gas and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly.