How to recycle used tyres?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

Used tyres

With the gradual improvement of people's living standards and the rapid development of the logistics industry, the number of private cars and the number of trucks in China have increased year by year. The increase in the number of vehicles has led to economic development, while the consumption and wear of automobile tires has also produced a lot of garbage - used tyres. A few years ago, used tyres were thrown away as garbage, which greatly polluted the environment we lived on. At this time a new industry is quietly emerging, this is - recycling of used tyres.

There are several ways to recycle old tyres after they have been replaced:

Used tyres be sold to the hawkers

First, the master who sells or gives the tyres or the hawker who collects the tyres or sells them to the waste collection, and then the tyre repairer and the scrap collector are sold to the hawkers who collect the tyres.

1. The less worn (used to be used) is sold to the driver for continued use;

2. It can be refurbished or fire-fighted and sold to the person who is refurbished or fire-fighted or in the hands of the ladle processor, and then passed through the tire repairer or directly sold to the driver to continue to use;

3. The worn-out tyres (discarded) will be sold to the corresponding processing plant for splitting or refining, and then further deep processing;

4. It can be made into various rubber products directly into rubber products, such as steel cord fabric, nylon cord fabric, old tire basin and so on.

Second, throw it at home or sell it later or discard it directly.

Compared to the above-mentioned re-refurbishment, or sold to hawkers, the used tyres pyrolysis plant process uses the latest pyrolysis technology to convert used tyres into oil, carbon black and steel wire. The main advantages of the used tyre pyrolysis plant working process are zero emissions and high efficiency.

Used tyres pyrolysis plant

Using the used tyres pyrolysis plant can not only solve the problem of wasting tire pollution, but also bring you more profit than re-refurbishing the fire or selling it to the hawker. So what is the used tyre recycling process using the latest pyrolysis technology?

Used tyres pyrolysis plant process

Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The used tyres pyrolysis plant reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically. When the temperature fall to 100℃, workers could open the door of the reactor to discharge the rest steel wire.

Lastly, the released gas can achieve national emission standard through the dedusting system.

Used tyres pyrolysis plant final products

After the entire used tyres pyrolysis plant working process , 45-50% of fuel oil, 30% of carbon black, 15% of steel wire, and 5% of combustible gas can be obtained. These substances have a very wide range of uses in life, as follows:

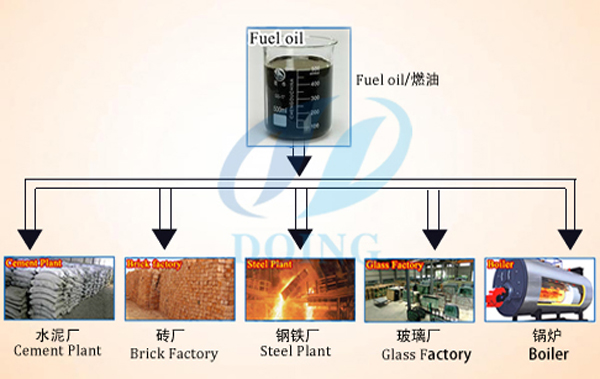

Fuel oil application

1. 45-50% fuel oil: Mainly used for steel factory,boiler heating,heavy oil generator,cement factory.

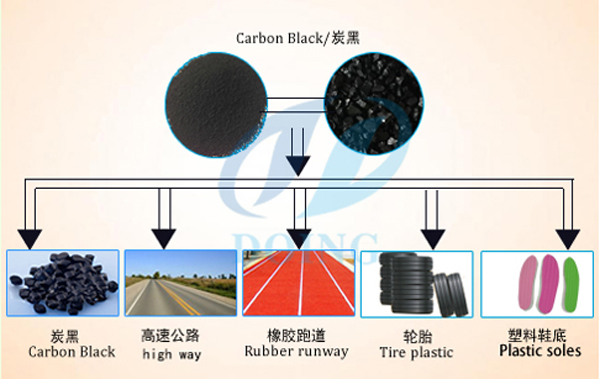

Carbon black application

2. 30% carbon black: Can be sold to the market,also could be further processed before selling.At present ,there are mainly 2 processing ways for carbon black.One is briquetting ,another is granding.After granding the pyrolysis carbon black to N550,N660,N774 and other semi-refinforced carbon black,they could be used for making many kinds of rubber products.

3. 15% steel wire: Mainly sold as scrap or remelting.

4. 5% flammable gas: Can be recycled by the pyrolysis plant ,then used for the reactor fuel gas.

Used tyres pyrolysis plant installed in Lebanon

From the used tyres we usually throw away, we can get so many substances, and these substances have such a wide range of uses in our lives. Are you particularly interested in the recycling of used tyres through our latest pyrolysis technology? For more used tyres pyrolysis plant details, please contact us!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications