How to recycling plastic to oil ?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

Recycling waste plastic to oil machine

Recycling plastic to oil ?

Recycling waste plastic to oil machine

Step -1 Put plastic material into the pyrolysis reactor by mechanical feeding machine or manual, then it is delivered into the store bin with the help of conveyor belt. Then, close the feeding door and open heating system of the machine.

Step – 2 In this step, two stages are there in the process. The primary stage: the heat energy needs to start with 100 degree Celsius and ending with 250 degree Celsius. In 100 degree Celsius, the oil gas will release and in 120 degree Celsius the liquid oil will release. The secondary stage: the heat energy needs to change from 250 degree Celsius towards 280 degree Celsius; it is the peak output rate. The oil gas will be collected into the manifold, and the oil as well as the weighty particles are accumulate and dissolved in the center of the manifold and drop into the deep oil container (oil tank). And the lighter oil gas will certainly go up to multifunctional oil condensers to liquefy into oil and keep in the tank.

Step – 3 Cool down the plastic to oil conversion plant after the completion of Step-1 and Step-2. Once the heat reaches about 40 degree Celsius, the carbon black will be discharged automatically.

Step – 2 In this step, two stages are there in the process. The primary stage: the heat energy needs to start with 100 degree Celsius and ending with 250 degree Celsius. In 100 degree Celsius, the oil gas will release and in 120 degree Celsius the liquid oil will release. The secondary stage: the heat energy needs to change from 250 degree Celsius towards 280 degree Celsius; it is the peak output rate. The oil gas will be collected into the manifold, and the oil as well as the weighty particles are accumulate and dissolved in the center of the manifold and drop into the deep oil container (oil tank). And the lighter oil gas will certainly go up to multifunctional oil condensers to liquefy into oil and keep in the tank.

Step – 3 Cool down the plastic to oil conversion plant after the completion of Step-1 and Step-2. Once the heat reaches about 40 degree Celsius, the carbon black will be discharged automatically.

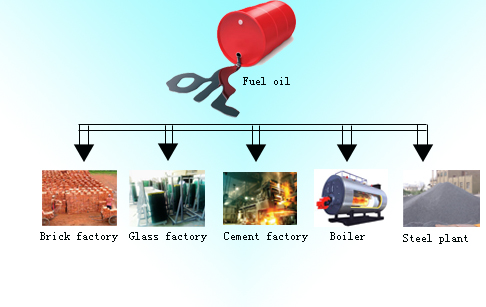

Fuel oil application

1. Fuel oil: the fuel oil is the first production and has an immeasurable value. You know that oil is nonrenewable resource and deficient energy. The fuel oil can be further reprocessed into diesel and gasoline by Doing group oil distillation plant.

It also can be used as industrial fuel materials for burning.

It also can be used as industrial fuel materials for burning.

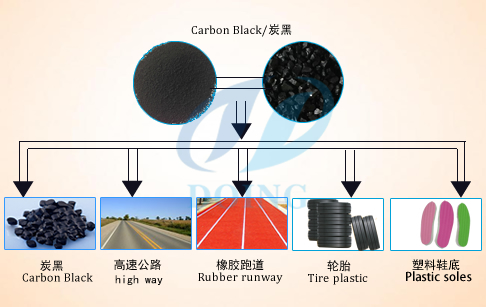

Carbonb black application

2. Carbon black: the carbon black is the necessary production and has wide applications. We can sell it directly for making money. It can be made carbon brick by briquetting equipment for building or reprocessed into high quality carbon by carbon brick processing plant for burning or sale. In a word, they are popular and valuable in the current market.

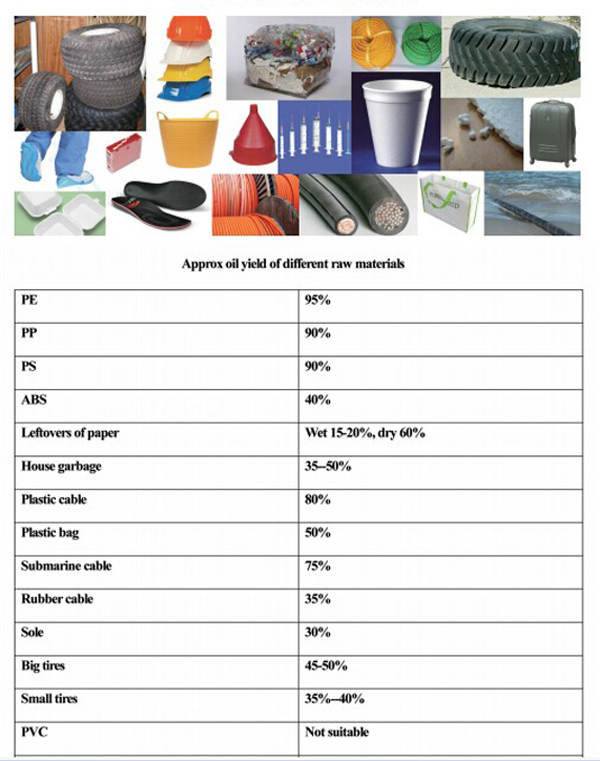

Different kinds waste plastic oil yield

Of course,different waste plastic have different oil yield! In order to let you have a deeper understanding of recycling plastic to oil, we have summarized the above oil yield table for different waste plastics, for your reference!

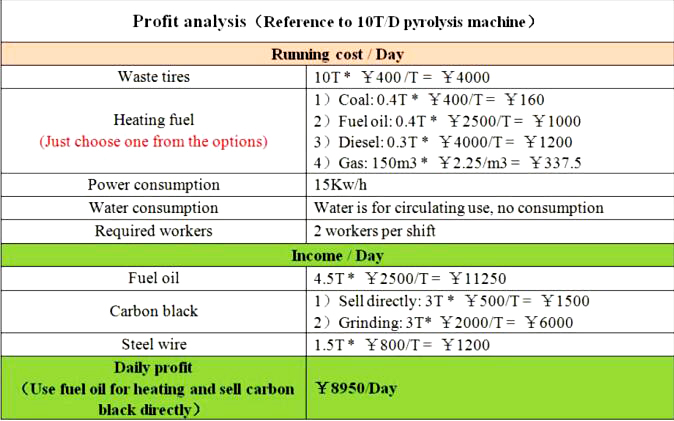

Through the recycling plastic to oil working process, you can final get the fuel oil,carbon black as concerned above. Mybe the profits analysis is your most want to know about the recycling plastic to oil pyrolysis plant. Compared with the most manaufacturers,choose our pyrolysis plant ,you can avoide environmental issues! We have took the environment into consideration during the engineer designed the pyrolysis plant!Following is the specific profits analysis of the pyrolysis plant:

Through the recycling plastic to oil working process, you can final get the fuel oil,carbon black as concerned above. Mybe the profits analysis is your most want to know about the recycling plastic to oil pyrolysis plant. Compared with the most manaufacturers,choose our pyrolysis plant ,you can avoide environmental issues! We have took the environment into consideration during the engineer designed the pyrolysis plant!Following is the specific profits analysis of the pyrolysis plant:

Recycling plastic to oil pyrolysis plant profits analysis

The above daily profits is taken 10T pyrolysis plant as example foryour reference ,we have different capacity of the recycling plastic to oil pyrolysis plant! Just tell us the capacity you want to investment,we will send you the detail information!And we have professional engineer team,they can offer the spot installation guidence and running test!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications