What's pyrolysis technology?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

The use of pyrolysis technology is rapidly expanding globally as environmental concerns and price volatility of energy resources continue to increase. More and more investors are attracted by waste pyrolysis technology.

Waste raw materials to energy pyrolysis technology

Waste raw materials to energy pyrolysis technology

Pyrolysis technology is a thermal process that breaks down organic materials such as waste plastics, tires, rubbers, oil sludge, coal tar, PCB, biomass, etc. into useful products such as pyrolysis oil, syn-gas, and carbon black through heating in the absence of oxygen. The word pyrolysis comes from Greek "pyro" meaning fire and "lysis" meaning separating.

The process occurs in a pyrolysis reactor where the organic material is heated to a high temperature in the absence of oxygen. This results in the decomposition of the material into the aforementioned useful products. Here we made a final product application picture of pyrolysis technology for your reference.

Final products applications of pyrolysis plant

Final products applications of pyrolysis plant

Pyrolysis oil is one of the most important final products. The pyrolysis oil can be used as fuels for power/electricity generation plants, furnaces, boilers, steel/brick/cement making factories, etc. You can also refine the pyrolysis oil into diesel to improve its color, smell, ordor and quality by DOING waste oil distillation plant.

Pyrolysis technology offers a sustainable waste management solution since it is capable of diverting a significant amount of waste from landfills while creating value from these wastes. The technology is also an environmentally friendly alternative to traditional waste disposal methods such as incineration, which can result in harmful emissions. That's why more and more people engage in the pyrolysis business.

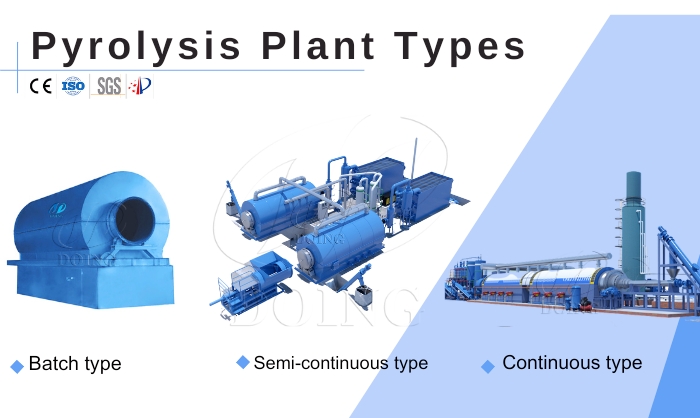

Then how many types of pyrolysis technology and which one is the best technology? As a professional pyrolysis plant manufacturer and supplier, Henan Doing Company offers answers here.

DOING Company pyrolysis technology types

DOING Company pyrolysis technology types

There are mainly three kinds of pyrolysis technology: batch type, semi-continuous type, and the fully continuous types. They have different capacities, features and are suitable for different customers. You can contact Henan Doing Company and tell us your situations and requirements, then the best pyrolysis plant technology solutions will be provided.

| Pyrolysis technology types | Capacity | Features |

| Batch pyrolysis technology | 100KG-20TPD | Cost effective, easy operation, good stability |

| Semi-continuous pyrolysis technology | 10-20TPD | High effiency, energy saving, good perfromance |

| Fully continuous pyrolysis technology | 15-50TPD | 24 hours continuous pyroduction, high automatic degree, high profits |

We have adheres to the principle of "Quality First, Credit Foremost" to customize suitable pyrolysis technology solutions for our customers. And our waste pyrolysis plant got a lot of good feedback from customers in more than 90+ countries and regions. We are looking forward to cooperating with more customers to achieve a win-win!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications