How is fuel oil from plastic waste?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

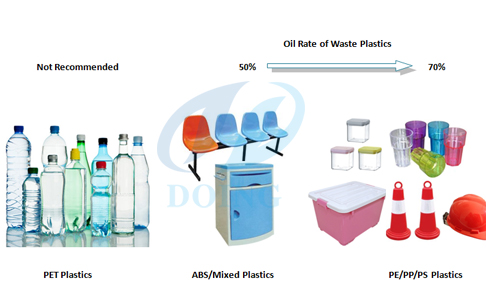

Plastic to fuel oil oil yield

Fuel oil from plastic waste machine

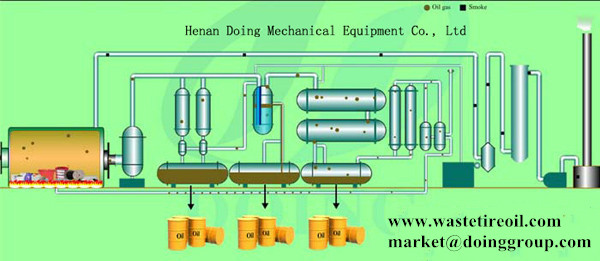

1.Fuel oil from plastic waste pyrolysis technology is not overly complicated. plastics are shredded and then heated in an oxygen-free chamber (known as pyrolysis) to about 400 degrees celsius. As the plastics boil, gas is separated out and often reused to fuel the machine itself.Fuel oil from plastic waste?

Plastic to fuel oil working process

2. The fuel oil from plastic waste machine includes two stages. From 100℃ to 250 ℃ is the preliminary stage. The light oil gas shall be released at 100 ℃ and fluid oil shall be released at 120℃ . From 280℃ to 350℃is the top output rate interval. Oil gas will be collected into manifold, heavy particles and oil will be gathered and liquefied in center of manifold and drop down into the heavy oil tank. The lighter gas will rise up to the multi-functional oil condensers, then be liquefied into oil and stored in the oil tank. The incondensable gas through de-sulfuration and de-dusting by hydroseal will be led to heat the furnace for reducing the energy cost.

3. By the general way, you need to cool down the plastic pyrolysis reactor after the process.Carbon black will be discharged automatically when the temperature falls down to 50-70 degrees.The cooling down process need 4-5 hours ,waste the precious operation time!But this year ,our engineer team have designed the Air suction system for discharging carbon black.Here are the main advantages of the system:

The previous and new design carbon black system comparsion

A.The first domestic manufacturer who owns this technology.

B.On the one hand ,the Air suction system for discharging carbon black doesn't need so much time as the general carbon black slagging system.On the other hand ,Compared with the previous screw conveyor, it adopts the straight up and down type conveying method to reduce the time for slag discharge.Both of those two hands decides the shorter discharging time by the new carbon black discharging system.

C.Save land space and reduce investment costs.

D.The collected carbon black is more concentrated, which facilitates later loading and transportation.

E. Maintenance is simple.

Fuel oil application

The plastic pyrolysis oil can be sold directly as fuel. Or be transformed into gasoline or diesel by the plastic oil distillation plant. The refined plastic pyrolysis oil can be used for heavy oil generator to produce electricity.

After you know , how is fuel oil from plastic waste? And know the detail application of the main products-fuel oil,you must want to know the profits analysis of fuel oil from plastic waste,following chart is the profits analysis for your reference!!

| Profit analysis (Reference to 10T/D pyrolysis machine) | |

| Running cost/Day | |

| Heating fuel | 10T*400/T=RMB 4000 |

| Power consumption(Choose one from the options) | 1)Coal:0.4T*RMB400/T=RMB160 |

| 2)Fuel oil:0.4T*RMB25000/T=RMB1000 | |

| 3)Diesel:0l3T*RMB4000/T=RMB1200 | |

| 4)Gas:150m3*RMB2.25/m3=RMB337.5 | |

| Power consumption | 15Kw/h |

| Water consumption | Water is for circulating use,no consumption |

| Required workers | 2 workers per shift |

| Income/Day | |

| Fuel oil | 4.5T*RMB2500/T=RMB11250 |

| Carbon black | 1)Sell directly:3T*RMB500/T=RMB1500 |

| 2)Grinding:3T*RMB2000/T=RMB6000 | |

| Steel wire | 1.5T*RMB800/T=RMB6000 |

| Daily profits(Use fuel oil for heating and sell carbon black directly) | RMB8950/Day |

How is fuel oil from plastic waste? With the further increase of the global energy crisis and the country’s emphasis on environmental protection, this issue has now become very urgent. Choosing DOING's waste plastic pyrolysis plant can not only recovery of fuel oil from plastic waste, but also various emissions can be up to the national environmental assessment standards, which is your best choice for investment!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications