How to make diesel oil from waste plastic?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

How to make diesel oil from waste plastic - plastic waste oil refining process - (Henan Doing Mechanical Equipment Co., Ltd. )

diesel oil from waste plastic process

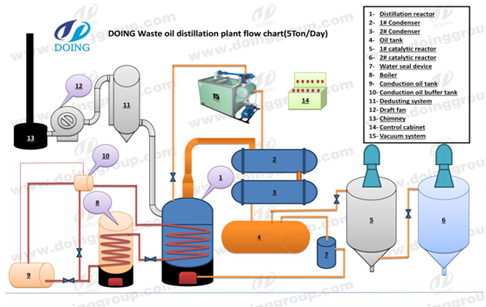

diesel oil from waste plastic process. After the first removal of debris and sediment contained in waste plastics ( without removing the can, but will affect the oil yield ) , the waste plastic pyrolysis reactor is loaded , make pyrolysis cracking reaction , the waste plastic pyrolysis oil and gas again small molecular state , through the condenser into liquid into the fractionator , after fractionation mixed oil output by re- refining and cracking can be processed into diesel fuel.Main features of diesel oil from waste plastic plant:

1. Fast.

The unique fast heating system is especially designed for shorten working time.

In market, mostly are horizontal reactor or old design for plastic to diesel distillation machine which take about 3-5days to finish one batch.

2. Easy slagging

Vertical reactor make slagging from bottom automatically and fast.

3. Energy saving

Fast heating system keep temperature even after slagging and you can use for next batch so is energy saving.

4. Safe

Strict quality control system and professional safety devices guarantee our plastic to diesel distillation machine running safely and win a good reputation from customers.

5. Environmental friendly

Professional dedusting systems ensure our diesel oil from waste plastic plant runs zero pollution.

Henan Doing Mechanical Equipment Co., Ltd provide production of plastic refining equipment , which can effectively be discarded plastics , tires and other raw materials through processing, refined into diesel fuel, waste recycling is a good device , the device environmentally friendly is the preferred plastic refining equipment.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications