Home>FAQ>Waste Tyre Recycling Pyrolysis PlantWhat are the important components of waste tire pyrolysis plant?

Home>FAQ>Waste Tyre Recycling Pyrolysis PlantWhat are the important components of waste tire pyrolysis plant?

What are the important components of waste tire pyrolysis plant?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

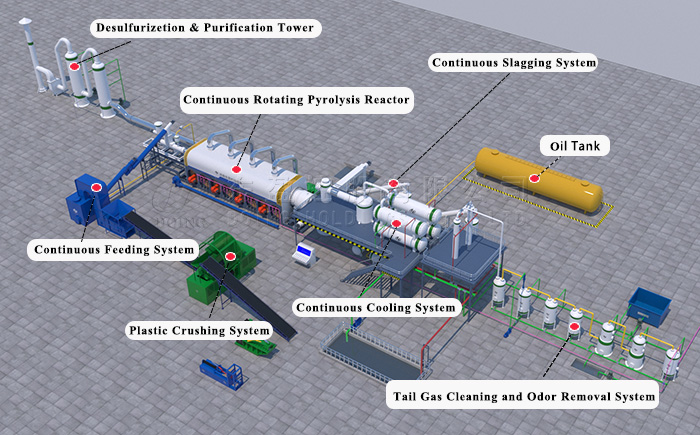

Some customers many heard of waste tire pyrolysis plant, but don't know much about the components and the functions of these components of waste tire pyrolysis plant. Generally speaking, the key components of waste tire pyrolysis plant includes pyrolysis reactor, cooling system, environmental protection system and safety devices. Here, I'll take Doing Group waste tire pyrolysis plant as an example to introduce the components, customers can as a reference when purchasing waste tire pyrolysis plant.

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

1. Pyrolysis reactor.

Pyrolysis reactor is the most important component of waste tire pyrolysis plant, which is the place where pyrolysis reaction takes place. Doing Group adopts 16mm Q245R boiler plate to produce the pyrolysis reactor. The Q245R boiler plate could make the pyrolysis reactor bear high temperature heating,and 16mm thickness of the pyrolysis reactor plate is the best choice by considering about the heat transfer factor. Also our pyrolysis reactor is welded by auto-welding technology with three-step welding to make sure the welding of the pyrolysis reactor is perfect, thus to avoid the crack during long time high temperature operation.

Pyrolysis reactor

Pyrolysis reactor

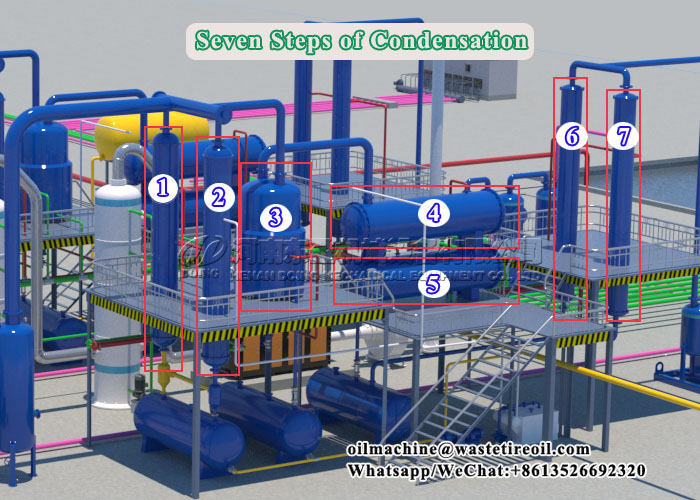

2. Cooling system.

The cooling system can cool oil gas down into fuel oil, so the quality of cooling system directly affect the oil yield. Doing Group waste tire pyrolysis plant adopts three steps cooling system, the cooling area is 1.5 times that of oil gas, and the heat exchange area is large, so the oil gas can be fully cooled and get high oil yield.

Cooling system

Cooling system

3. Environmental protection system.

In order to avoid causing secondary pollution to the environment during the working process of waste tire pyrolysis plant, Doing Group waste tire pyrolysis plant equipped with perfect environmental protection system, including tail gas cleaning system and smoke cleaning system, which can effectively purify the bad smell and harmful gas produced in the pyrolysis reaction, and can meet the national gas emission standard.

Environmental protection system

Environmental protection system

4. Safety devices.

The safety devices of Doing Group waste tire pyrolysis plant include Oil-water separator, Water seal and Vacuum device. Oil-water separator is mainly used for preventing the back flow of oil gas, while water seal is for preventing the back flow of the tail gas, and the vacuum device could provide negative pressure to the system, thus to keep safe operating pressure.

Safety devices

Safety devices

In addition to the above main components, Doing Group also provides some auxiliary equipment to improve the production efficiency,such as automatic feeding machine, tire packing machine, carbon black ball press machine, carbon black grinding machine,etc. If you want to know more information about waste tire pyrolyisis plant,welcome to consult us.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications