Waste tyre recycling pyrolysis plant for sale

Waste tyre recycling pyrolysis plant

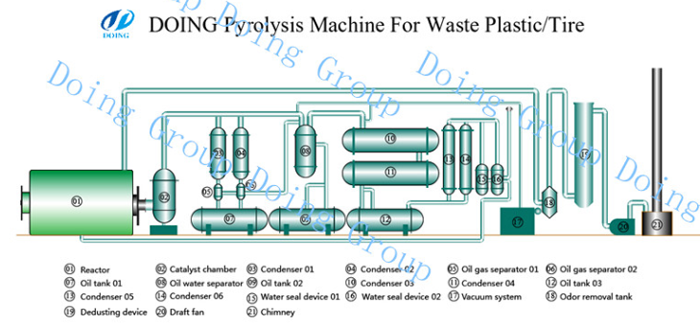

Working processes of waste tyre recycling pyrolysis plant:

Waste tyre/plastic recycling pyrolysis plant working flow chart: automatic feed → catalytic cracking → oil-water separation → cooling liquid → carbon black emission → carbon black processing → crude oil → flammable gas recovery → flammable gas combustion → dust removal

Waste tyre recycling pyrolysis plant working process

Let’s see the workers operation details:

1. Loading raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Keep heating the furnace until the temperature reaches nearly 250 degree Celsius, at this temperature, waste tyres will be transferred into oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected into big oil tank.

3. The exhaust gas which can’t be cooling into liquids in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

4. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

5. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

6. When the temperature falls to 100 degree Celsius, worker could put steel wire hook to reactor to take steel wire out. After all these steps, you can start another batch.

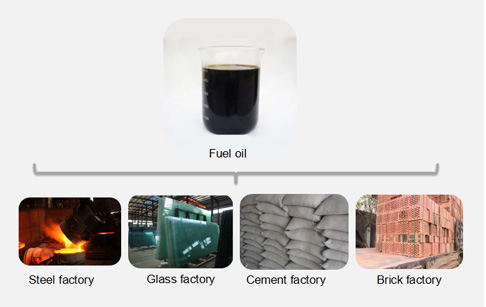

Fuel Oil (45% to 52%)

Fuel oil application

Steel Wire (12% to 15%)The third product of Waste tyre recycling pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire in local market.

Carbon Black (30% )

Carbon black

The second product of waste tyre recycling pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Oil gas (About 10%)

We get about 10% oil gas during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.