How to refine the tank bottom petroleum sludge?

Industry News / Chat online / Give me a price / 2024-01-09

There is a lot of crude oil produced and used every year, and during transportation, lots of tank bottom petroleum sludge will be produced. If it's processed improperly, it will produce large pollution, but if it's processed and refined properly, it can bring lots of benefits to us. While oil sludge pyrolysis machine is the most suitable method among these recycling ways.

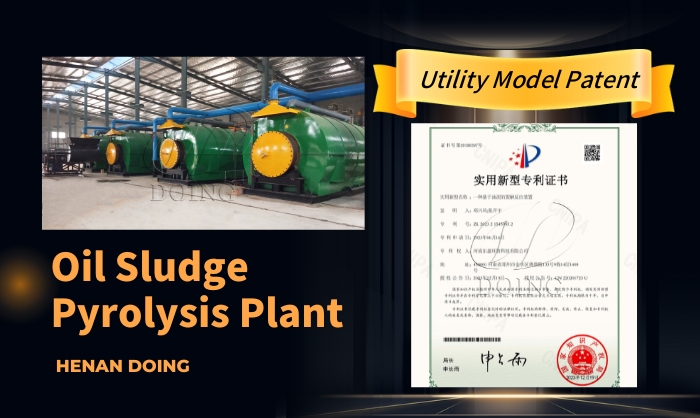

DOING oil sludge pyrolysis machine for sale

DOING oil sludge pyrolysis machine for sale

The oil sludge pyrolysis machine could extract the fuel oil in the tank bottom petroleum sludge, separating the fuel oil from the sand or soil completely. Usually, after being refined by an oil sludge pyrolysis machine, there is just 0.002% oil remaining in the tank bottom petroleum sludge, that’s almost the dry soil or sand, which could be used to make brick or other civil construction. And the extracted fuel oil can be used as heating fuels in some heavy oil industries, such as cement factories, steel factories, glass factories, heavy oil generators, power plants, etc.

During the cooperating process in the past several years with our customers, DOING has been committed to enhancing the designs of our oil sludge pyrolysis machine, and now we have the special design oil sludge pyrolysis machine especially for the tank bottom petroleum sludge and other oil sludge. It’s designed with an anti-coking structure, more suitable for processing the oil sludge with high oil content.

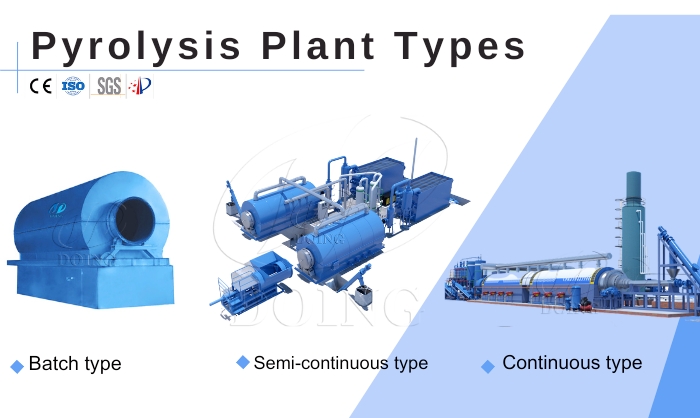

Three types of DOING oil sludge pyrolysis machine

Three types of DOING oil sludge pyrolysis machine

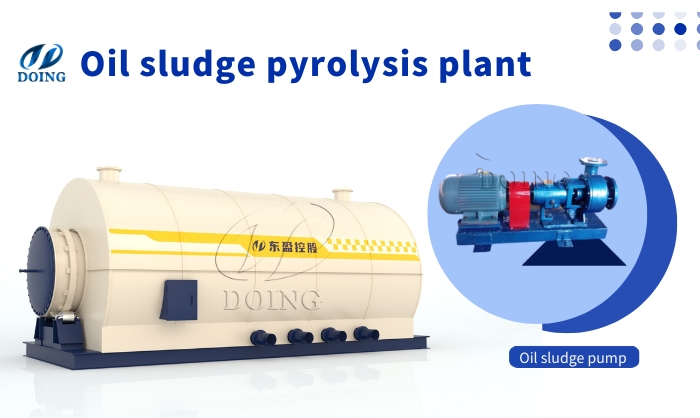

And we have researched different types of oil sludge pyrolysis machines with different capacity, configuration and designs to recycle different types of oil sludge. If the oil containment of your oil sludge is small, less than 50%, and the oil sludge is the solid type, we suggest you use the semi-continuous oil sludge pyrolysis machine, which can feed oil sludge while the machine is running, having high working efficiency. But if your oil sludge is the liquid type, we suggest you use the batch type oil sludge pyrolysis machine or the waste oil distillation machine, equipped with a special pump to feed the oil sludge directly.

Pump that is equipped with the oil sludge pyrolysis machine

Pump that is equipped with the oil sludge pyrolysis machine

For the oil sludge pyrolysis machine, we have the different processing capacities from 100/500KG to 30/50 tons per batch. If you have little oil sludge to recycle or just want to have a test for the oil sludge pyrolysis machine business, the small capacities like 100/500 kg, 1/2 tons per batch will be more suitable, and the operation cost is also affordable. and if you have a larger investment scale or want to enlarge your business scale, you can select the larger capacity type. Of course, if you don't know how much processing capacity is appropriate, just contact us, our sales manager will help you customize the suitable scheme.

Materials that suitable for oil sludge pyrolysis machine

Materials that suitable for oil sludge pyrolysis machine

DOING oil sludge pyrolysis machines have been put into operation successfully in many countries, and apart from the above mentioned tank bottom petroleum sludge, other oil sludge like oil sand, waste oil spills, coal tar oil, etc. also can be refined with oil sludge pyrolysis machine. So for any questions about the oil sludge refining, welcome to contact us directly!