Is pyrolysis of plastic feasible? Can it bring profit?

Industry News / Chat online / Give me a price / April 22, 2020

Nowadays waste plastic pyrolysis plant is more and more popular with customers home and abroad. Pyrolysis of plastic has attracted the attention of many investors. Some investors may wonder is pyrolysis of plastic feasible? Can it bring profit? The answer is yes. Follow with me, please, and I will have a detailed introduction to these problems. Next, I will introduce pyrolysis of plastic feasible from three aspects: economic profit, environmental protection and safety.

Pyrolysis of plastic is feasible and profit

Pyrolysis of plastic is feasible and profit

1. Economic profit

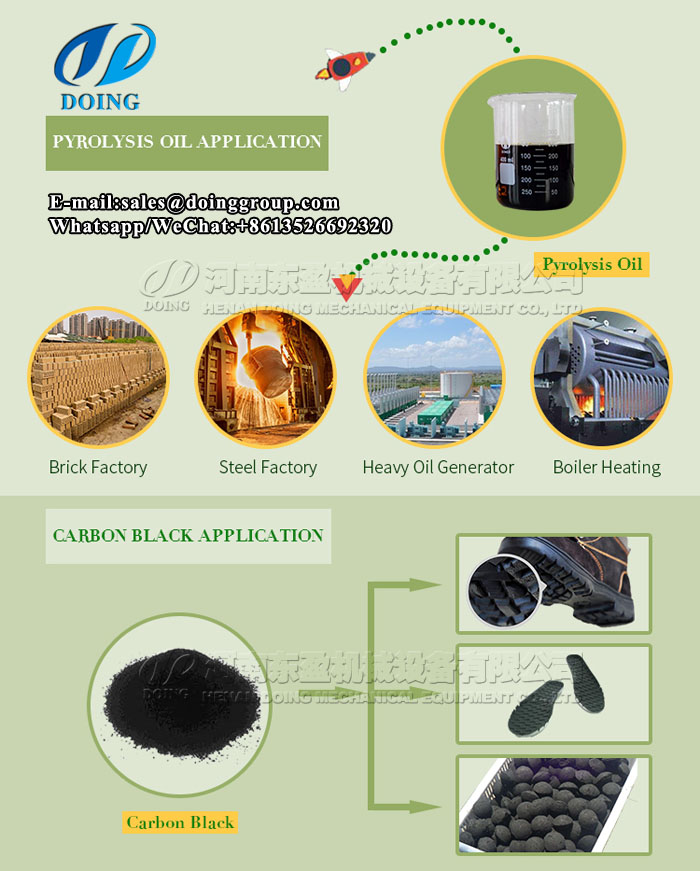

As we all know, without any process, plastic waste just is a headache pollution problem due to its difficult degradation. However the pyrolysis of plastic can convert plastic waste into fuel oil and carbon black. The fuel oil has a high heating value, and widely used in many industries such as steel factories, glass factories, cement factories, ceramic factories, brick factories, boiler heating etc. Carbon black can be directly sold or processed again used as an additive in the manufacture of rubber products.

Application of final products from waste plastic pyrolysis plant

Application of final products from waste plastic pyrolysis plant

In a word, it is a good heating fuel substitute and can apply to all those industries which need heating. Also, it is already proved by our customers that the plastic fuel oil has very good market in many countries. Depending on the market outlook and price of these fuel oils, the pyrolysis of plastics into oil has a large profit margin.

In addition, some gases produced among pyrolysis of plastic contain a non-condensable gas. It will be directly recycled for heating the pyrolysis reactor which can reduce the operation cost.

2. Environment friendly

During the pyrolysis process of plastic, the probable pollution sources are water and gas pollution. All the water used in plastic pyrolysis processing is circulation water, which is used for cooling down oil gas into fuel oil and has no any contact with oil gas. Therefore, the water is no consumption, no pollution. To avoid smoke and tail gas pollution, DOING waste plastic pyrolysis plant have been designed professional water dust scrubber, exhaust gas deodorization device, desulfuration dedusting tower. After processed by these devices, 80%-90% harmful emissions could be removed from gas thus can meet the emissions standard. Carbon black collection device can ensure no dust pollution in the process of carbon black slag discharge.

DOING special device designed for pyrolysis plant

DOING special device designed for pyrolysis plant

3. Safety

DOING waste plastic pyrolysis plant have many special safety devices to ensure machine’s safety running, such as safety valves, alarming bell, thermometer. Besides, we also spent a lot on machine design to make sure safety like the track design of supporting roller, corrugated tube, buffer, oil water separator, water sealing, vacuum, etc. For example, negative pressure system can remove the oil gas from pyrolysis reactor and ensure the safe operation of the pyrolysis plant .

Till now, our waste plastic pyrolysis plant has been successfully implemented in more than 70 countries, such as Italy, Romania, Turkey, Macedonia, Albania, Egypt, Nigeria, Kenya, India, Bangladesh, Iran, Thailand, Malaysia, Indonesia, Australia, Mexico, Panama, Ecuador, Columbia etc. Among of them, there are many customers return orders to us.

DOING pyrolysis of plastic projects all over the world

DOING pyrolysis of plastic projects all over the world

To sum up, pyrolysis of plastic is feasible and has a good profit margin. If you still have any doubt about the feasibility of plastic pyrolysis, welcome to contact us for more information.