New technology of plastic to oil machine and waste oil distillation plant

Company News / Chat online / Give me a price / December 29, 2014

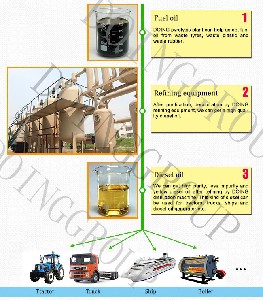

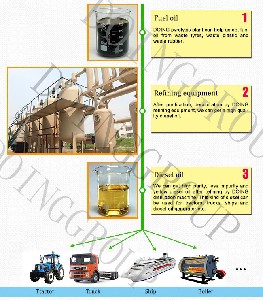

Scrap plastic to oil machine technology is mainly to convert plastic to fuel oil. Also called plastic to oil pyrolysis plant, used plastic pyrolysis plant and so on. Usually there are two machines used together. One is Scrap plastic to oil machine, this machine can convert scrap plastic to fuel oil (also named crude oil, furnace oil, pyrolysis oil etc). Another one is waste oil distillation machine, It can refining waste engine oil (plastic oil, tyre oil, waste oil etc) into diesel fuel. In this step the oil is of great quality can used directly for tractors,trucks, power generator and so on. Among all the advantages the raw material of the Scrap plastic to oil machine is easily achieved with high profit.

Scrap plastic to oil machine features:

The reactor of scrap plastic to oil machine is adopts Q245R plate. Indirect heating method ensures the machine safety and pro-long plastic to oil machine service life. The rubber is softened after which the rubber polymers continuously breakdown into small molecules. Then the vapors can be burned directly in the reactor, or it can be condensed into oily type liquid. Usually, it is called oil. During the conversation there are some vapors which cannot be condensed will be recycled to heat the reactor itself. It is energy saving. Well designed dedusting system ensures no pollution to environment.

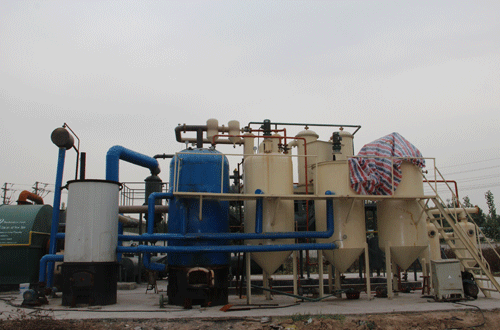

Waste oil distillation plant is a new technology which designed by Henan Doing Mechanical Equipment Co.,Ltd. Distillation plant has a oil recovery rate about 85%.

Diesel fuel applications:

Diesel oil application

Scrap plastic to oil machine |

Waste oil distillation plant |

Scrap plastic to oil machine features:

The reactor of scrap plastic to oil machine is adopts Q245R plate. Indirect heating method ensures the machine safety and pro-long plastic to oil machine service life. The rubber is softened after which the rubber polymers continuously breakdown into small molecules. Then the vapors can be burned directly in the reactor, or it can be condensed into oily type liquid. Usually, it is called oil. During the conversation there are some vapors which cannot be condensed will be recycled to heat the reactor itself. It is energy saving. Well designed dedusting system ensures no pollution to environment.

Waste oil distillation plant is a new technology which designed by Henan Doing Mechanical Equipment Co.,Ltd. Distillation plant has a oil recovery rate about 85%.

Diesel fuel applications:

Diesel oil application