Home>Product>Tyre/Plastic Oil to Diesel Distillation PlantPyrolysis oil refining process distillation plant

Home>Product>Tyre/Plastic Oil to Diesel Distillation PlantPyrolysis oil refining process distillation plant

Pyrolysis oil refining process distillation plant

Tyre/Plastic Oil to Diesel Distillation Plant / Chat online / Give me a price

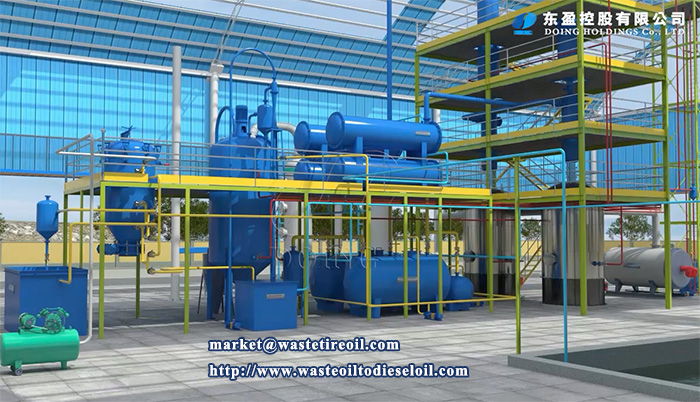

Pyrolysis oil refining process distillation plant adopts the green technology to realize the distillation of the crude tyre/plastic pyrolysis oil and waste motor oil and finally gets diesel oil. With the rapidly development of world economy, oil resource has been becoming more and more important in our life. Thus, this new energy way has been on the agenda in many countries. The following are the main introduction of pyrolysis oil refining process distillation plant.

Pyrolysis oil refining process distillation plant

Pyrolysis oil refining process distillation plant

Pyrolysis oil refining process distillation plant main working process

1. The heat conduction oil is heated by the heat conduction oil furnace, and then the heat conduction oil flows into the coil pipe which is inside the distillation reactor, and the crude tyre/plastic pyrolysis oil is heated in the distillation reactor. Using this heating method can better control the temperature and is conducive to the following operation.

2. As the temperature increases, the pyrolysis oil produces oil gas and flows into the buffer tank. There are fillers in the buffer tank, which can purify the oil gas, control the oil gas emission rate, and prevent the oil from the distillation reactor from entering the catalytic tower and causing the solid catalyst of the catalytic tower to fail.

3. With the further increase of temperature, oil gas from the distillation reactor into the catalytic tower, in the catalytic tower there are two kinds of catalysts: catalyst A for absorption, catalyst B for cracking. Through the catalytic tower, the oil gas are split into small molecules of oil, and out of the deep color.

4. After passing through the catalytic tower, small molecules of oil gas are cooled into liquid oil through the cooling system and collected into the oil tank.

5. After all the oil gas is evaporated, the remaining in the reactor is hot asphalt, which can be directly pumped out by the asphalt pump.

Main working process of pyrolysis oil refining process distillation plant

Main working process of pyrolysis oil refining process distillation plant

Pyrolysis oil refining process distillation plant advantages

1. Pyrolysis oil refining process distillation plant has high oil yield.The crude tyre/plastic pyrolysis oil or waste motor oil recovery ratio is about 90% by the treatment of solid catalyst tower. When the water content is less than 5%, the ratio can even exceed 95%.

2. Pyrolysis oil refining process distillation plant mainly uses solid catalyst which is easy to buy and easy to transport.

3. High on-stream efficiency without corrosion, fouling, and coking.

4. Featured with environment protection operation tech and devices. In and after the process, no soil, water or air pollution exists.

5. It is easy to clean and maintain with vertical structure design.

6. It creates an alternative of energy to replace petroleum products and natural gas.

Main final products and their application

We can get diesel and asphalt from pyrolysis oil refining process distillation plant. The diesel fuel can be used in tractors, trucks, ships and diesel oil generators etc. Asphalt can be used to pave roads.

Diesel fuel application

Diesel fuel application

Most customers are also concerned about the pyrolysis oil refining process distillation plant profits,we have conclude the equipment profits analysis for your reference.

Pyrolysis oil refining process distillation plant profits analysis

| ROI Analysis For 5T/D Oil Distillation Plant | |

| Running Cost / Day | |

| Waste oil | 5Ton * 262USD/Ton = 1311USD |

| Heating fuel (Diesel) | 0.4Ton * 699USD = 280USD |

| Catalyst | 87USD |

| Electricity | 15Kw/h * 0.14*20h = 44USD |

| Water | Water is for circulation use, no consumption |

| Worker | 2 * 15USD = 30USD |

| Income / Day | |

| Light oil (Diesel & Gasoline) | 4Ton * 699USD = 2897USD |

| Oil sludge | 0.75Ton * 160USD = 120USD |

| Profit / Day | 1166USD |

Pyrolysis oil refining process distillation plant project case

DOING company has been focusing on pyrolysis oil refining process distillation plant manufacturing for more than 10 years, and our equipment has been sold to more than 60 countries around the world. As shown in the figure below.

Pyrolysis oil refining process distillation plant project cases

Pyrolysis oil refining process distillation plant project cases

In addition, DOING company also provides a full range of after-sales services to customers who purchase our pyrolysis oil refining process distillation plant to eliminate your worries. If you are interested in purchasing our pyrolysis oil refining process distillation plant, please contact us continuously for free quotation.