Home>FAQ>Waste Tyre Recycling Pyrolysis PlantWhat we are achieving from waste tyre pyrolysis to oil process?

Home>FAQ>Waste Tyre Recycling Pyrolysis PlantWhat we are achieving from waste tyre pyrolysis to oil process?

What we are achieving from waste tyre pyrolysis to oil process?

Waste Tyre Recycling Pyrolysis Plant / Chat online / Give me a price

What we are achieving from waste tyre pyrolysis to oil process?

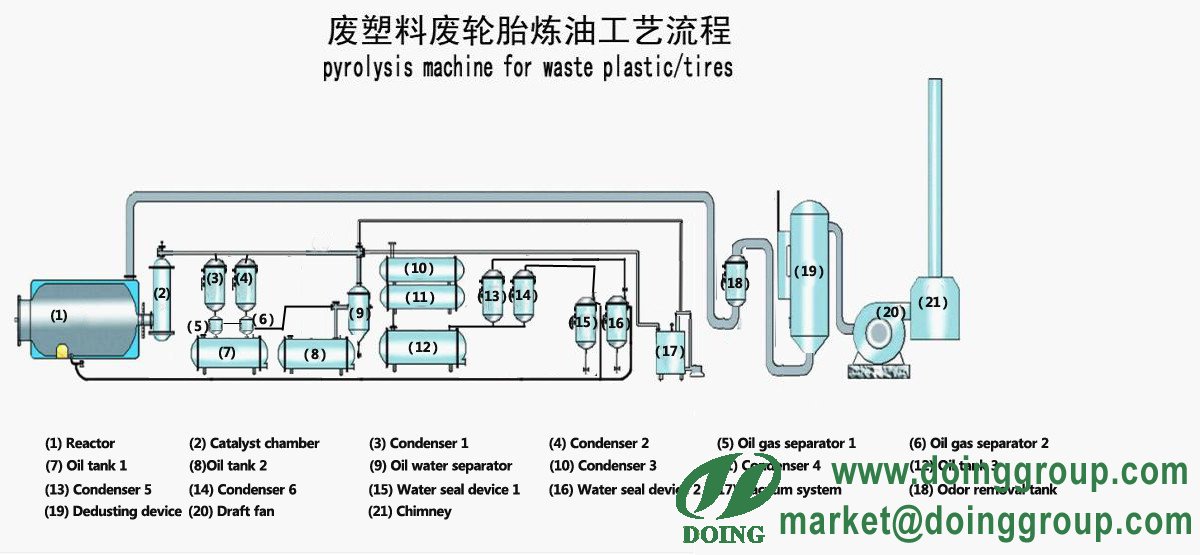

Waste tyre pyrolysis to oil process

From waste tyre pyrolysis to oil process we are achieving following energy forms

- Fuel Oil (45%52%)

- Carbon Black (30 to 35%)

- Steal wire (10 to 15 %)

- Gas (5 to 8 %)

So, thus we are achieving almost 100% of tyre pyrolysis to oil process. And this is most cost effective waste tyre pyrolysis technology in the world. There are Three type of waste tyre pyrolysis to oil machine

1) 5 Ton waste tyre pyrolysis to oil machine

2) 8 Ton waste tyre pyrolysis to oil machine

3) 10 Ton waste tyre pyrolysis to oil machine

The process of Pyrolysis has duration of 16 to 20 hours, depending on the amount and type of tyre. Benefits of Waste tyre pyrolysis to oil machine.

- Waste tyre pyrolysis to oil machine are environment friendly

- Generate energy source from the waste

- Waste tyre plant are cost effective compare to other energy generating process

- safe and reliable process

- Each recycled ton of tyre preserves 10 tons of CO2 that is a major greenhouse gas.

Henan Doing Mechanical Equipment Co., Ltd is manily supply the best waste tyre pyrolysis to oil machines sppliers in China with has an engineer and sales team of experienced and expert recycling, consulting and marketing professionals that work hard for obtaining renewable energy from the waste.

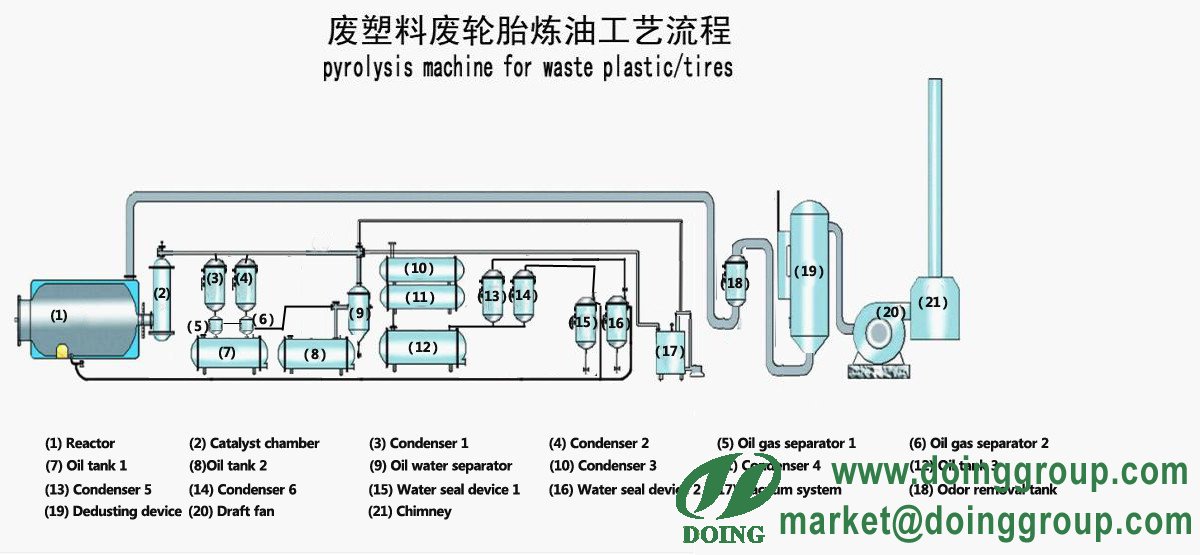

Waste tyre pyrolysis to oil process

From waste tyre pyrolysis to oil process we are achieving following energy forms

- Fuel Oil (45%52%)

- Carbon Black (30 to 35%)

- Steal wire (10 to 15 %)

- Gas (5 to 8 %)

So, thus we are achieving almost 100% of tyre pyrolysis to oil process. And this is most cost effective waste tyre pyrolysis technology in the world. There are Three type of waste tyre pyrolysis to oil machine

1) 5 Ton waste tyre pyrolysis to oil machine

2) 8 Ton waste tyre pyrolysis to oil machine

3) 10 Ton waste tyre pyrolysis to oil machine

The process of Pyrolysis has duration of 16 to 20 hours, depending on the amount and type of tyre. Benefits of Waste tyre pyrolysis to oil machine.

- Waste tyre pyrolysis to oil machine are environment friendly

- Generate energy source from the waste

- Waste tyre plant are cost effective compare to other energy generating process

- safe and reliable process

- Each recycled ton of tyre preserves 10 tons of CO2 that is a major greenhouse gas.

Henan Doing Mechanical Equipment Co., Ltd is manily supply the best waste tyre pyrolysis to oil machines sppliers in China with has an engineer and sales team of experienced and expert recycling, consulting and marketing professionals that work hard for obtaining renewable energy from the waste.